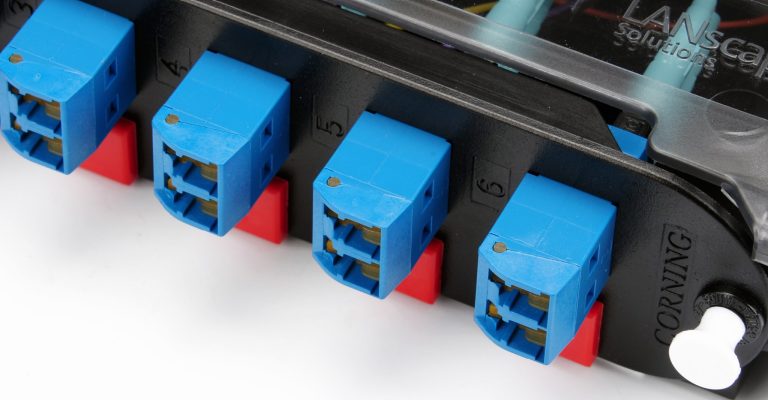

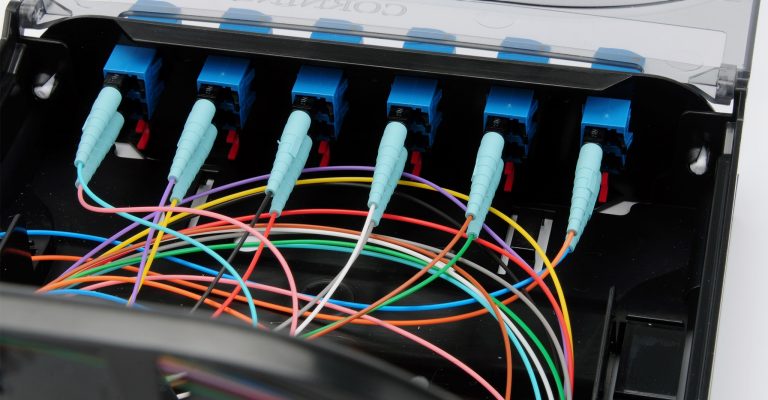

Fiber optic fusion splicing is on the rise and Corning's Pigtailed Splice Cassettes enable faster field splicing and easy modular management of connectorization within the housing. Pre-routed and preloaded, pigtailed splice cassettes reduce installation time by up to 40%.

Faster Fiber Optic Splicing

Faster Fiber Optic Splicing

The Philosophies of Fiber Optic Fusion Splicing

|

|

Rise of the Splice Machines New and old technology combine to drive pigtailed cassette-based termination. Read the article today. |

Top Tips: Investing in Fiber Fusion Splicing

The evolution of fusion splicing technology makes it easier to invest in what has become an increasingly popular fiber termination method to meet today’s increasing network demands.

-

Only Use Active Clad Alignment for Same-Era Fiber

Fiber consists of a central core, cladding that surrounds the core, and a protective coating. A single-mode fiber has a coating that typically measures 250 microns, a cladding of 125 microns, and a core of 8 microns. An active clad alignment splicer aligns the outer edges of the cladding by holding the fibers in a v-groove using electrodes as they move along an x- and y-axis, using cameras to assist with analyzing the alignment. Clad alignment is not recommended when splicing modern-day fiber with previous generations of fiber. Over time, fiber manufacturers have succeeded in improving fiber geometry, and the core concentricity will likely differ. When fiber cores are not the same concentricity, alignment can be off and the signal will not have an optimum path, resulting in signal loss at the splice location, degrading or preventing transmission.

-

Achieve Greater Accuracy with Core Alignment

Instead of focusing on aligning the outer edges of the fiber’s cladding, core alignment promotes light moving uninterrupted through the fiber core based on its properties. For example, because light moves differently through the core than the cladding, it glows brighter at the core. Core alignment solutions provide greater accuracy when splicing single fibers, especially when splicing two fibers that may not have the same core concentricity.

-

Choose a Mass Fusion Splicer for Ribbon Fiber

With increasing bandwidth demands, fiber counts have increased. To fit more fibers into a small footprint, manufacturers use ribbon fiber where 12 color-coded fibers are grouped together. A fiber cable can contain multiple tubes packed with ribbon fibers, arranged either flat and stacked or rolled, enabling fiber counts in a single cable to reach as high as 6,912! Mass fusion splicers should be used for splicing ribbon fiber as they allow all 12 fibers to be fused simultaneously, significantly saving time and money. These splicers use clad alignment technology with multiple v-grooves to align all 12 fibers, but advancements in mass fusion splicing have increased accuracy closer to that of core alignment solutions.

-

Embrace the Variety of Applications

To meet bandwidth demands and high-speed application loss requirements, fusion splicing has significantly grown in popularity. The industry has catapulted away from simple cable-to-cable splicing long employed for restoration and repairs in outside plant single-mode applications to now encompass a diverse application portfolio across a multitude of environments. Cable-to-pigtail splicing has become increasingly popular in inside plant applications for repairs, adds, moves, or changes. Used with both single- and multimode fiber and either single or ribbon fiber, pigtail splicing has become the de facto choice for terminating incoming outside plant fiber to indoor fiber at the building entrance or demarcation point with splices typically residing in rack- or wall-mounted enclosures. Depending on the type of fiber, core or active clad alignment solutions are both effective for pigtail splicing. Also used in inside plant applications, splice-on connectors have become increasingly popular for use with both single-mode and multimode fiber, and either single or ribbon fiber. They offer a reliable, low-loss method for easily terminating tight-buffered indoor fiber to single-fiber, duplex-fiber, or multifiber connectors.

-

Easily Justify Your Investment in Fiber Optic Fusion Splicing

Early fusion splicing equipment was expensive, cumbersome, and labor intensive often requiring a team of two or three people to manually splice in a protected environment, qualify with an OTDR, and oversee the process. Today’s fusion splicing equipment is far less expensive depending on the application and features. They can be easily run by one person, feature intuitive touchscreen interfaces, and are highly portable. Fusion splicers have also advanced to deliver a very close loss estimation during the splicing process and incorporate a pull test after the fibers are fused, eliminating the need for continuous testing during the splicing process. With its ability to support growing bandwidth demand and enable higher transmission speeds, the number of applications requiring fiber is on the rise. Manufacturers are working to make fiber optic cables easier to install, repair, and update. Fusion splicing is now crucial for contractors to meet the network demands of today.

See Termination in Action

See Termination in Action

Get a clear, practical look at fusion splicing technique as we install a FuseLite® 2 field-installable connector using a KF4 fusion splicer. The video walks through fiber preparation, cleaving, fusion, protection, and inspection—highlighting tips for low-loss, repeatable results in traditional LAN environments. Whether you’re splicing in the field or into pigtailed cassettes, these best practices help streamline installs and support consistent network performance.

Watch Video Below

Pigtailed Cassette Resources

Get Started Today!

Whether you need help with current data demands or planning for the future, we can help. Complete this form to get started today.

Thank you!

Thank you for contacting us. A Corning representative will be contacting you shortly about your inquiry. Should you need immediate assistance please all our customer service line at +1 800-743-2675.