These networks must withstand extreme conditions while meeting the demands of AI, edge computing, and real-time analytics. However, labor shortages, complex installations, and environmental challenges are slowing progress as data demands continue to surge. This article explores how ruggedized, pre-terminated optical fiber can simplify deployment, reduce reliance on specialized labor, and enable scalable networks in the most challenging settings.

As industries embrace digital transformation, ICT networks must deliver high performance in harsh environments such as factory floors, oil fields, and transportation corridors.

As industries embrace digital transformation, ICT networks must deliver high performance in harsh environments such as factory floors, oil fields, and transportation corridors.

RELIABLE INFRASTRUCTURE IN HARSH ENVIRONMENTS

RELIABLE INFRASTRUCTURE IN HARSH ENVIRONMENTS

The Rise of Harsh Environment ICT Applications

The accelerating pace of digital transformation across industries is driving demand for ICT networks capable of operating under extreme conditions. Industrial sectors such as manufacturing, utilities, and transportation are increasingly reliant on robust infrastructure to ensure reliability. For example, smart factories depend on real-time data and automation to optimize production, utilities require continuous monitoring and control of vital systems, and intelligent transportation systems rely on seamless connectivity to manage traffic flow, logistics, and safety. These critical applications are pushing ICT deployments into environments that challenge conventional infrastructure.

What sets these applications apart are the harsh environmental conditions, including high heat, moisture, vibration, and electromagnetic interference (EMI).1 For example, optical fiber networks in steel mills must endure intense heat and mechanical stress, while those in wastewater facilities must resist corrosion and moisture.

Addressing these challenges requires ruggedized components and resilient network designs capable of maintaining uptime and performance despite physical and environmental stressors. The expansion of ICT networks in these sectors is not only about connectivity—it is about engineering networks that can thrive in environments where failure is not an option.

The Urgency of Reliable Infrastructure

Emerging technologies such as AI, machine learning, and edge computing are revolutionizing industrial operations, enabling real-time decision-making, automation, and predictive analytics. These capabilities, however, depend on networks that deliver high bandwidth, low latency, and uninterrupted performance—even in the harshest environments.

In these industrial applications, the volume and speed of data are unprecedented. Sensors generate continuous streams of information that feed into intelligent systems, which analyze, learn, and act in real time. Edge computing further enhances this process by reducing latency and enabling immediate responses to critical events. This evolution places pressure on network infrastructure to be not only fast but also resilient and scalable.

To meet these demands, organizations must design robust networks that can withstand environmental stress while supporting advanced applications— because in these mission-critical settings, downtime is not an option.

MARKET FORCES SHAPING THE FUTURE

MARKET FORCES SHAPING THE FUTURE

Infrastructure Investment Trends

Recent government initiatives to remake America into a manufacturing superpower have led to several billion-dollar investments, especially in AI, automotive, pharmaceutical, and energy sectors. In addition, key legislative acts such as the Infrastructure Investment and Jobs Act (IIJA) and the Creating Helpful Incentives to Produce Semiconductors (CHIPS) and Science Act have provided substantial funding and tax incentives to bolster these sectors.2

The nationwide transportation sector is also going through a large-scale expansion and upgrade, from airports and seaports to highways and roadways, resulting in significant growth of intelligent transportation systems.3,4 These investments are set to modernize the country's infrastructure, address critical needs in various sectors, and ensure long term economic growth and stability. Many of these large-scale projects utilize state-of-the-art technologies, which drive the demand for higher bandwidths and lower latencies to ensure seamless data transfer and real time analysis. This positions optical fiber as an integral enabler of future technological growth in these sectors.

2.2 Labor Shortages and Project Bottlenecks

With ICT deployments expanding into harsh environments—and investment pouring in from both public and private sectors—a pressing question arises: Who will install these networks? The future of ICT from an installation perspective hinges on solving a growing challenge: a shortage of skilled labor.

As demand for hyperscale and enterprise data centers rises, the industry faces a critical gap in qualified optical fiber technicians, especially those skilled in high-precision splicing and cabling. According to the Uptime Institute’s 2024 Global Data Center Survey, 71% of operators cite staffing shortages as a major concern, with over half struggling to hire optical fiber infrastructure roles.5 This shortage is not just a matter of quantity but of specialization. In response, many are turning to pre-terminated optical fiber systems and modular infrastructure to reduce on-site labor needs and accelerate timelines. These solutions are no longer just about efficiency— they are essential to keeping pace with the scale and complexity of modern ICT installations. By simplifying deployment and reducing reliance on specialized labor, they help ensure that infrastructure projects can move forward despite workforce constraints.

ENVIRONMENTAL AND TECHNICAL CHALLENGES

ENVIRONMENTAL AND TECHNICAL CHALLENGES

Physical and Electromagnetic Hazards

It is important to understand the environmental stressors that can complicate installations in harsh environments. Physical hazards include vibration, moisture, and mechanical impacts that can damage network components.1 For instance, vibration can cause connectors to loosen, while moisture can lead to corrosion and short circuits. Electromagnetic hazards, such as EMI, can disrupt the signal integrity of the network. These all can lead to installation challenges, quality issues, and network downtime.

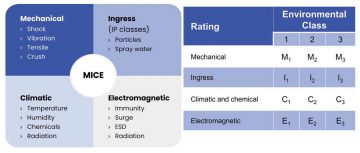

The Mechanical, Ingress, Climatic/Chemical, and Electromagnetic (MICE) rating system, as defined by ISO/ICE 24702 standard, is a classification framework used to evaluate the robustness of cabling systems and components in industrial environments (Figure 1). MICE provides four levels of environmental classifications for each of these categories:6

- Mechanical (M): This category assesses the cabling system's ability to withstand physical stressors such as shock, vibration, tensile forces, and crushing. The classifications range from M1 (least severe) to M3 (most severe).

- Ingress (I): This category evaluates the protection against the ingress of dust and water. The classifications range from I1 (least severe) to I3 (most severe).

- Climatic/Chemical (C): This category measures the cabling system's resistance to climatic and chemical conditions, including temperature fluctuations, humidity, chemicals, and radiation. The classifications range from C1 (least severe) to C3 (most severe).

- Electromagnetic (E): This category assesses the cabling system's ability to withstand EMI, including surge, electrostatic discharge (ESD), and radiation. The classifications range from E1 (least severe) to E3 (most severe).

Network Performance Demands/Network Performance Expectations

The resilience and uptime of network infrastructure are paramount, especially in mission-critical systems. These systems must operate reliably under extreme conditions such as high temperatures, moisture, vibration, and EMI. Ensuring network uptime in these environments is vital to maintaining continuous operations and avoiding costly downtime.

By understanding these environmental stressors and selecting components with appropriate MICE ratings, contractors can ensure their installations can withstand the test of time, enhancing both their reputation and building customer trust and loyalty.

WHY OPTICAL FIBER IS THE FUTURE

WHY OPTICAL FIBER IS THE FUTURE

Optical Fiber vs. Copper in Harsh Environments

As industrial networks evolve to support data-intensive applications, the limitations of copper and coaxial cabling in harsh environments are increasingly clear. Optical fiber cabling offers a durable, high-performance alternative that resists EMI, corrosion, and signal degradation over long distances—without requiring boosters or repeaters. Optical fiber’s ability to withstand extreme temperatures, moisture, and vibration makes it ideal for demanding settings like manufacturing floors, utility substations, and transportation systems. It delivers the high bandwidth and low latency needed for real-time monitoring, AI/ML analytics, and edge computing, while reducing maintenance costs compared to copper systems.7 Beyond performance, optical fiber ensures long-term scalability and sustainability. Its extended lifespan and bandwidth allow networks to grow without costly upgrades.8 In harsh or mission-critical environments, optical fiber is not just a better option—it is the only one that meets the demands of modern ICT network infrastructure.

Rethinking Installation Design

This is the inflection point: legacy practices should transition to optical fiber-centric, modular designs that align with the realities of industrial-scale data, edge computing, and constrained labor resources.

RUGGEDIZED PRE-TERMINATED OPTICAL FIBER SOLUTIONS

RUGGEDIZED PRE-TERMINATED OPTICAL FIBER SOLUTIONS

What They Are

Ruggedized pre-terminated optical fiber solutions are factory-terminated, sealed, and tested cable assemblies that are ready to deploy out of the box. These systems are highly adaptable, offering a range of configurations from partial pre-terminated assemblies to fully plug-and-play solutions.

Key components typically include:

- Hardened plug & play connectors: Designed for quick, secure mating in outdoor or industrial settings, often with weatherproof seals and robust locking mechanisms.

- Rugged terminals and hardware: For flexible deployment that can go anywhere (in cabinets, poles, enclosures, or wherever needed).

- Factory-terminated optical fiber cables: Eliminate the need for splicing and the amount of skilled labor required on-site.

Modular design options: Allow partial or full pre-termination, depending on the site’s layout and installation strategy. This modularity allows network designers to tailor the solution to the specific needs of the site and architecture—whether it is a centralized backbone or distributed edge deployment.

Why They Matter

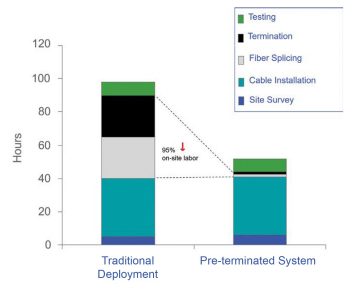

1. Faster, Simpler Installations (Figure 2)

- Eliminates on-site splicing with pre-terminated assemblies.

- Reduces installation time significantly – ideal for projects with tight deadlines.

- Requires fewer tools and fewer steps, meaning fewer opportunities for error.

2. Reduced Dependence on Skilled Labor

- Helps bridge the technician shortage by minimizing the need for specialized skills.

- Enables smaller crews to complete more work faster.

- Improves consistency and quality across deployments.

3. Safer and More Reliable in Harsh Environments

- Factory-sealed and tested for durability in extreme conditions (e.g., moisture, vibration, EMI).

- Lowers risk of field-related failures or rework.

- Ideal for remote or hazardous locations where access is limited.

4. Lower Total Cost of Ownership

- Reduces labor and tool costs during installation.

- Fewer maintenance interventions over time due to rugged construction.

- Long service life minimizes downtime and replacement needs—reducing long-term operational costs.

5. Scalable and Future-Ready

- Modular designs support easy upgrades and expansions.

- Avoids costly infrastructure overhauls as bandwidth and infrastructure needs grow.

Where They Work

Ruggedized pre-terminated optical fiber solutions are designed for deployment across a wide range of environments—from clean, climate-controlled data centers to the most demanding industrial and outdoor settings. Their adaptability makes them ideal for both enterprise and industrial networks, where reliability, speed, and ease of installation are essential.

These solutions are commonly used at key network points such as splice locations, interconnect hubs, and access terminals. They are built to meet or exceed common outside plant (OSP) standards, ensuring they can withstand exposure to the elements, physical stress, and environmental hazards.

Key Verticals and Use Cases

- Manufacturing Facilities: Connect machines on the production floor, enable real-time monitoring, and support automation systems in environments with vibration, EMI, and temperature fluctuations.

- Oil & Gas Fields: Provide secure, high-performance connectivity in remote, rugged locations where safety and uptime are critical.

- Mining Operations: Enable communications and sensor networks in underground or open-pit mines, where dust, moisture, and mechanical stress are constant challenges.

- Campus and Industrial Sites: Support long-distance backbone connections between buildings, control centers, and edge devices across large facilities.

- Construction and Temporary Networks: Power portable data centers or temporary networks on construction sites, offering fast setup and teardown with minimal labor.

- Edge Applications: Connect locally powered devices such as surveillance cameras, environmental sensors, and intelligent transportation systems (ITS) infrastructure—often in roadside cabinets or pole-mounted enclosures.

Whether deployed in a permanent installation or a temporary setup, ruggedized pre-terminated optical fiber solutions offer the flexibility and resilience needed to support modern connectivity demands in virtually any environment.

KEY CONSIDERATIONS FOR DEPLOYMENT

KEY CONSIDERATIONS FOR DEPLOYMENT

Product Selection Criteria

When selecting ruggedized pre-terminated optical fiber solutions, consider the following criteria:

- Environmental Ratings: Ensure the products meet or exceed the MICE ratings required for the specific deployment environment.

- Ease of use: Hardened connectors and terminals come in various designs, ranging from large and complex to streamlined and foolproof. Opting for solutions that minimize installation errors and simplify deployment saves time and reduces the risk of costly mistakes.

- Cost vs. Benefit: Evaluate the total cost of ownership, including installation, maintenance, and potential future upgrades.

- Design and Planning: Take the time upfront for thorough site surveys and measurements to ensure precision in network design. Custom solutions often require additional lead time for manufacturing, so factor in production timelines in the planning process.

- Vendor Support: Choose vendors that offer comprehensive support, including technical assistance, training, and warranty services.

- Availability and Distribution Services: Explore flexible payment models and stocking options that help offset upfront costs. Consider kitting solutions, where common cable lengths and components are stocked on-site in ready-to-use kits, streamlining installation and replenishment processes.

LESSONS FROM PREVIOUS INFLECTION POINTS

LESSONS FROM PREVIOUS INFLECTION POINTS

We Have Seen This Before. Twice.

In the early 2000s, the fiber-to-the-home (FTTH) market faced a major bottleneck: the need for field splicing in the outside plant. This slowed deployments, increased labor costs, and introduced quality risks.

The solution? Hardened connectors and pre-terminated cable enabled plug-and-play architectures that dramatically accelerated FTTH rollouts (Figure 3). Similarly, the data center industry embraced preterminated, modular optical fiber systems to meet the demands of high-density, high-speed environments.

Plug-and-play solutions became the norm, reducing installation time, improving consistency, and supporting rapid scaling (Figure 4).

FIGURE 3: FTTH deployment timeline and key milestones pertaining to hardened connectors and pre-terminated cable adoption. Source: Corning

WHY ENTERPRISE ADOPTION IS ACCELERATING NOW

WHY ENTERPRISE ADOPTION IS ACCELERATING NOW

Today, enterprise and industrial environments are reaching a similar inflection point. Several factors are converging to make pre-terminated optical fiber not just viable—but essential:

- Labor Shortages: The scarcity of skilled optical fiber technicians is more acute than ever. Pre-terminated solutions reduce the need for specialized labor and enable faster, more consistent installations.

- Environmental Complexities: Harsh environments demand ruggedized, sealed, and factory-tested components. Pre-terminated systems eliminate the variability and risk of field splicing under difficult conditions.

- Edge Computing and AI/ML: These technologies require low-latency, high-bandwidth networks that are resilient and scalable. Pre-terminated optical fiber supports these demands with minimal disruption.

- Project Timelines and Funding Pressures: With government and private investment flowing into infrastructure, speed-to-deployment is critical. Pre-terminated solutions help meet aggressive schedules without compromising quality.

- Proven Track Record: The success of pre-terminated systems in FTTH and data centers provides a strong foundation. The technology is mature, field-tested, and ready for broader enterprise adoption.

CONCLUSION

CONCLUSION

The future of ICT isn’t just about faster speeds or smarter technologies—it is about how to build the networks that make them possible. As digital infrastructure expands into harsher, more complex environments, the installation process itself becomes a critical success factor. Labor shortages, environmental hazards, and rising performance demands are reshaping how networks are deployed. Ruggedized pre-terminated optical fiber solutions represent a pivotal shift—offering a scalable, efficient, and resilient approach that meets today’s challenges head-on. By minimizing the need for specialized labor and enabling rapid, high-quality installations, the systems are redefining what’s possible in ICT deployment. For organizations looking to stay ahead, the path forward lies not just in what networks can do—but in how seamlessly they can be installed, anywhere they are needed.

AUTHOR BIOGRAPHY:

Katherine Asbeck is a Market Development Specialist at Corning Optical Communications, where she plays a pivotal role in advancing enterprise network solutions. With expertise in event and product road maps, new solution introductions, and application support, she drives innovation via thought leadership and value proposition development. Katherine is dedicated to fostering strategic partnerships and expanding Corning's partner ecosystem while delivering impactful solutions to meet customer needs. She joined Corning in 2022 and holds a Bachelor of Science in Business Administration with a concentration in Marketing from the University of Richmond.

CITATIONS:

1. Reed, D., & Franklin, C. (2012). Fiber-optic cabling in strange and unusual places. Cabling Installation & Maintenance. Retrieved from https://www.cablinginstall.com/cable/article/16467186/fiber-optic-cabling-in-strangeand-unusual-places.

2. The White House. (2025, May 16). TRUMP EFFECT: A running list of new U.S. investments in President Trump’s second term. Washington, DC: The White House. Retrieved from https://www.whitehouse.gov/articles/2025/05/trumpeffect-a-running-list-of-new-u-s-investment-in-presidenttrumps-second-term/.

3. U.S. Department of Transportation, Bureau of Transportation Statistics. (2024). Transportation Statistics Annual Report 2024. https://doi.org/10.21949/e0kq-gf72

4. U.S. Department of Transportation. (n.d.). ITS DataHub: Intelligent Transportation Systems data from ITS JPO projects. https://www.its.dot.gov/data/

5. Uptime Institute. (2024). Global Data Center Survey 2024 (Keynote Report 146M, July 2024). Retrieved from https://datacenter.uptimeinstitute.com/rs/711-RIA145/images/2024.GlobalDataCenterSurvey.Report.pdf?version=0

6. International Electrotechnical Commission. (2023). IEC 61784-5-2:2023 – Industrial communication networks – Profiles – Part 5-2: Installation of fieldbuses – Installation profiles for CPF 2. Geneva, Switzerland: IEC.

7. Arrindell, G. (2024, July 11). How fiber is unlocking Industry 4.0 (the Fourth Industrial Revolution). Corning. Retrieved from https://www.corning.com/optical-communications/worldwide/en/home/the-signal-network-blog/the-fourthindustrial-revolution.html

8. Corning Inc. (2023). A sustainable future with optical fiber. https://www.corning.com/media/worldwide/coc/documents/Fiber/white-paper/WP1000.pdf.