When designing a fully-factory terminated cable that could be used for a data center interconnect, a specific challenges had to be addressed.

- The connectors had to be 100% protected from dust, debris, weather, and fluctuating temperature that are associated with a typical outside plant (OSP) installation environment.

- Insertion loss of the mated connector had to approach that of the incumbent splice and thus reduced relative to a traditional MTP

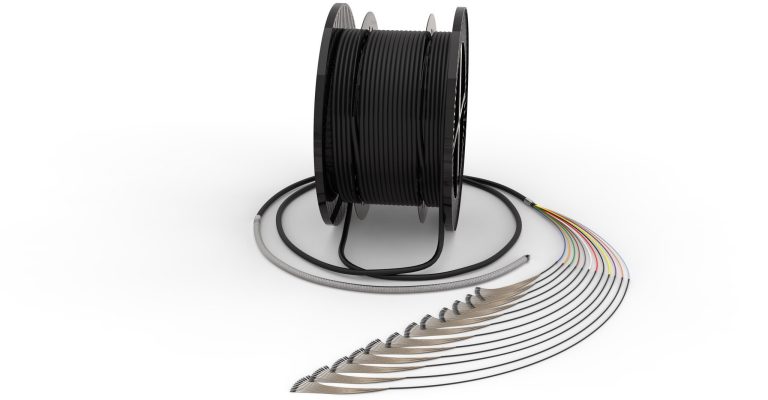

- The connectors had to be packaged in a protective and pulling grip less than 2.0 inches in outside diameter that would allow three cable assemblies to fit in a single 4-inch conduit space.

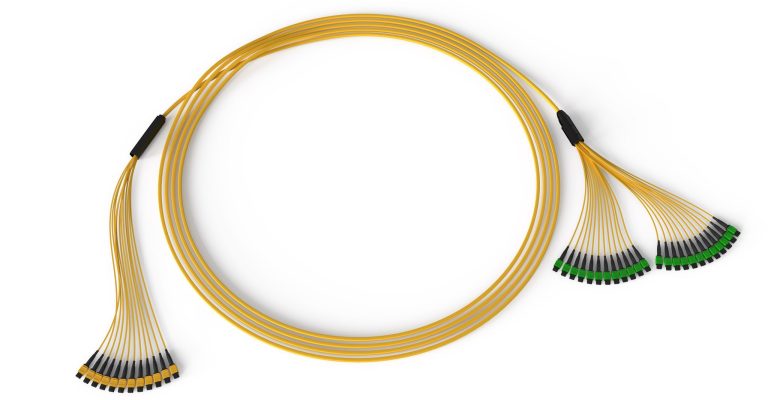

It was apparent, even with multiple staggered groups, the standard 12f MPO footprint was not optimized for meeting the grip size requirement. To enable a compact pulling grip that will protect the connectors through a harsh outside plant installation, the Fast Track MTP was utilized. The Fast Track MTP reduces the number of physical connectors in half by combining 24 fibers in a single Elite® ferrule that has a max IL of 0.35dB. To further reduce the outside diameter of the grip, the mechanical design allows the MTP connector body to be installed in the field after the cable is retained in the hardware (a 77% reduction in physical footprint of the MTP). To accommodate this, a thin secondary plastic “boot” is installed over the cable ribbon stack in the factory. The boot then serves as the basis for assembly and retention of the ferrule within the body of the connector. Once the boot is inserted into the rear of the MTP housing, capturing the MT ferrule in the process, the Fast Track MTP functions as a traditional 2x12 MTP® with a 12.5mm shroud and can be mated in a standard or reduced flange MTP Type-A adapter to interconnect with an Inside Plant (ISP) EDGE Rapid Connector Breakout cable. For quick and easy identification of ribbons while patching, each plastic boot is labeled with its respective connector number. Compare the cable preparation involved, fiber identification, inconsistency of splices, and complexity of a splicing operation to that of the pre-measured, pre-connectorized patching platform in the following photographs. After installation into the cable path, the pulling grip is removed thus presenting the pre-connectorized ribbon fibers already sub-unitized, labeled, and ready to be installed in their respective housing adapters - no furcating, splitting, nor tools required).

Our all-new case study is loaded with real world metrics and examples, resulting in a savings of up to 70% on installation time when installing trunk cables between data center buildings. Download your Case Study today!