Explore our Construction Products Regulation (CPR) frequently asked questions below. You can also download a hard copy for offline reference.

Frequently asked questions

Frequently asked questions

-

1. What are the EU directives and regulations related to construction products?

- CPD (Construction Products Directive 89/106/EEC)

- Construction Products Regulation (EU) No 305/2011 (CPR) adopted on the 9th of March, 2011

CPR adopted in March 2011 replaces the previous CPD and affects any organisation involved in the design, build, test, installation, and selection of construction products.

-

2. What is the purpose of the Construction Products Regulation?

- Ensures reliable information on construction products in relation to their performance

- Provides a “common technical language”, offering uniform assessment methods for the performance of construction products

- Applies to all construction products produced for, or incorporated within, building and civil engineering construction works

- Harmonises all construction products subject to regulatory controls for CE marking purposes

CPR is an EU effort to ensure all building materials are qualified in a manner to allow easy trade regardless of manufacturer or country of origin in regards to critical requirements of health and safety.

-

3. Who is affected by the CPR?

- Manufacturers when declaring the performance of their products

- Authorities of member states when specifying requirements for construction products

- EU accredited test institutes that will issue manufacturers with a declaration of conformity to standards

- Organisations (architects, engineers, constructors) when choosing the products for use in construction works

-

4. How does CPR address communication cables?

- Annex IV of the CPR identifies Product Area 31: Power, control, and communication cables

- Cables incorporated as a permanent part of the building construction need to be constructed and tested in accordance with CPR

This group of products concerns both fibre optic and copper datacom cables.

-

5. Which cables are not considered in the CPR regulation and must not be tested?

- Cables that are not permanently installed in buildings and all outdoor (duct, aerial, and direct buried) cables

-

6. Which are the burn tests and standards prior to CPR?

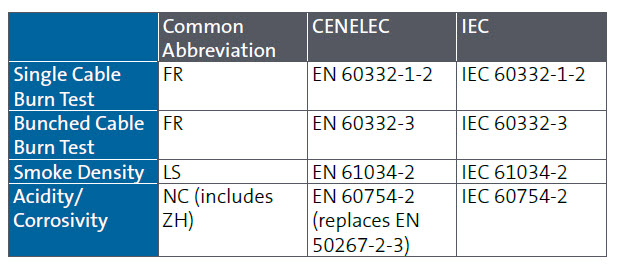

- Cable safety in respect to burning was expressed in terms of flame retardant and non-corrosive (FRNC) and/or low-smoke, zero-halogen (LSZH). For respective standards used, please see below table.

- FRNC/LSZH definitions have been superseded with a new approach for cable reaction to fire under CPR

-

7. Which standards are defining burn classifications of a cable?

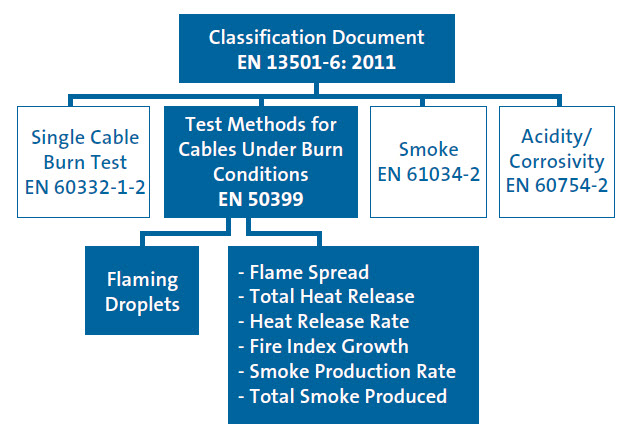

- EN 13501-6 is the leading standard within CPR and lays down the new test methods and performance criteria that must be met for a particular classification of cable

- It contains new standards for burn classification as well as older standards

Note: bunched test does not appear in the diagram above, but tests according to EN 50399 are conducted in a bunched configuration

- Burning behaviour of single cables (EN 60332-1-2) measures the flame spread of a cable under exposure to an open flame

- Smoke production of burning cables (EN 61034-2) measures the opacity/translucency of the smoke produced by a burning cable (opaque smoke may prevent occupants to safely escape buildings)

- Acidity levels produced by burning cables (EN 60754-2) measures the acidity or corrosiveness of the gas produced by a burning cable (gases are poisonous to occupants and may damage equipment or materials in the building)

- Burning behaviour of bunched cables (EN 50399) measures the reaction of bunched cables in the early stages of a fire, under direct exposure to a 20.5 kW flame source (Scenario 1) and a 30 kW flame source (Scenario 2)

Parameters measured include: flame spread (FR), total heat release (THR), heat release rate (HRR), fire index growth rate (FIGRA), total smoke produced (TSP), smoke production rate (SPR), and the number of droplets of flaming material. In addition there is another standard that applies to a new class of cables that are incombustible:

- The oxygen bomb calorimeter (EN ISO 1716) measures the heat flow while a material burns, as a material that releases high heat while burning may ignite other materials

-

8. What are the new classes defined in the CPR?

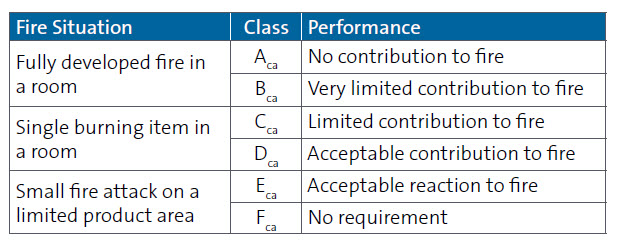

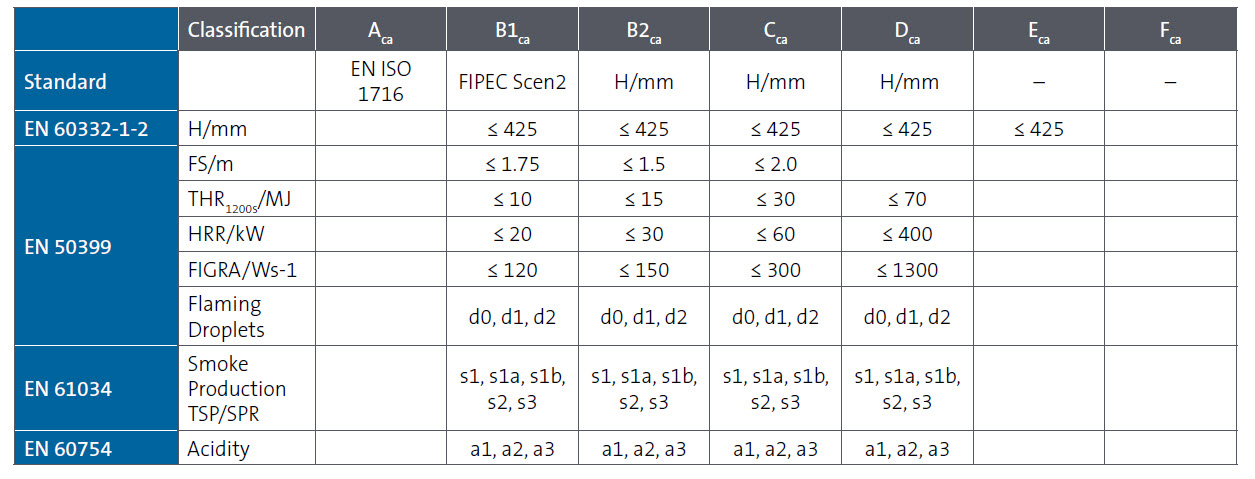

- CPR covers seven classes of cable, from Aca to Fca

- Classes are allocated on the basis of heat release and flame propagation criteria

- There are three supplementary classes for additional requirements: Production/emission (s), Acidity (a), and Flaming droplets (d)

- Aca – cables made out of non-combustible materials

- B1ca, B2ca, Cca, Dca, Eca – relevant for cables made out of combustible materials

- Fca – cables that have no fire protection at all

- Requirements for class Aca and B1ca are very stringent and currently cannot be fulfilled by cables consisting of thermoplastic halogen-free materials

Note: ca refers to cable

-

9. Who determines if a cable is compliant to CPR?

- In the EU the “notified body” is an accredited test institute defined by a member country (e.g VDE in Germany) that issues the Declaration of Conformity certificate

- The accredited test institute performs the initial measurement and rates the cable according to its performance

- Test assessments can include inspection and examination of a product, its design, and manufacturing process

- Declaration of Conformity allows manufacturers to label the product with the CE mark, which is required for distribution and sale in the EU

The notified body issues the Declaration of Conformity certificate to manufacturers. Manufacturers will only then be able to apply the appropriate CE mark to sell the product within the EU after marking became obligatory.

-

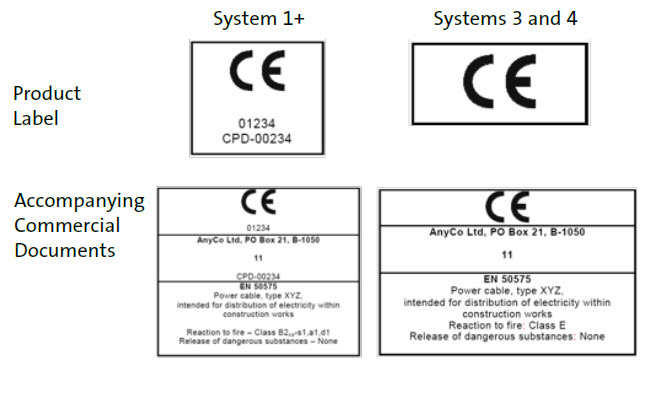

10. How will the CE marking look like and where will it be placed on a cable?

- Products complying with the new regulation will have CE marking that indicates the cable is both rated according to the standard EN13501-6 and conforms to the fire safety characteristics

- Cables and/or their packaging and/or labeling will be marked and carry obligatory (origin, manufacturer’s name, part number, fire classification) and additional elements (year, individual certification marks etc.)

Products complying with the new regulation will have CE marking indicating the cable’s rating in reaction to fire. The CE marking can be printed on the cable and/or on the package.

-

11. Will Fca cables (no fire protection at all) have to be labeled with a CE marking as well?

- Fca cables must carry a CE marking as well

-

12. When will the CE marking be obligatory?

- Before the standards, including CE marking, are enacted as a requirement, there is a transition period starting 1st of July 2016 in the EU member countries

Obligatory CE marking will start 1st of July 2017.

-

13. Are there national regulations in addition to CPR?

- Each EU member state has to enforce CPR and any necessary national designations

- In Germany : MBO (Musterbauordnung) and MLAR (Muster Leitungsanlagen Richtlinie) are still valid and have to be fulfilled - new EU classes (B2ca to Fca) correlate to German DIN classes (B1, B2, B3)

- Federal state governments of Germany decide on requirements of classes for specific applications (e.g. schools, hospitals, office) and special areas in a building (e.g. evacuation routes)

Existing national designations (e.g. DIN in Germany) are still valid. The transition or development of national designations in addition to CPR may need to take place in a number of countries.

-

14. Where can I find additional information?

- On the European Commission, Enterprise and Industry website http://ec.europa.eu/growth/sectors/construction/product-regulation/

- On the Corning website for future updates www.corning.com/opcomm/cpr