A unique focus on manufacturing processes drives success

Corning’s invention of low-loss optical fibre was a milestone that forever changed the communications landscape. But invention was only the first step. Without a way to manufacture optical fibre, with consistent reliability and performance, the invention would be futile.

Soon after inventing the fibre product, and even before a large order had been placed, Corning began developing the processes that would set the standard for optical fibre manufacturing excellence across the industry.

The root of this success? A steadfast and unique focus on and commitment to the processes and principles that drive manufacturing excellence across the globe.

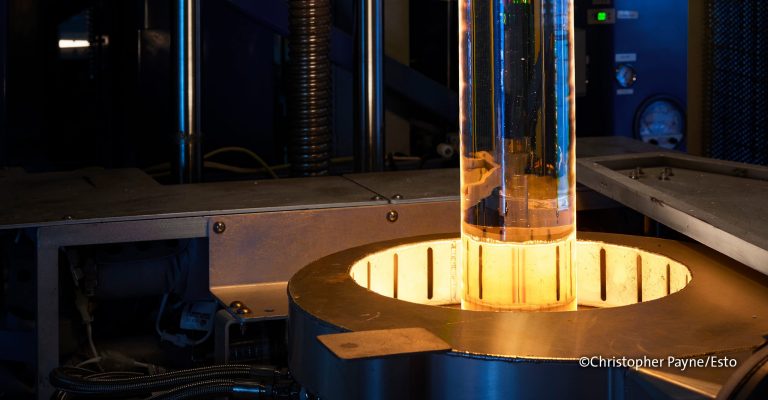

Corning produces all the glass for our optical fibre from raw materials, ensuring the highest quality and performance over the fibre's entire service life. This means that every strand of our fibre has full traceability to every step of our process, all the way back to raw materials.

Every step of our optical fibre manufacturing process is put through exacting and diligent quality control, providing unmatched performance characteristics including dispersion, attenuation, fibre geometry, and bandwidth. We design and build our optical fibre manufacturing equipment for process control and product consistency, and every centimeter of optical fibre produced is proof-tested to ensure it meets the highest strength requirements.

The results are unrivaled. With optical fibre manufacturing facilities across the globe – including multiple locations in the United States, China, India, and Poland – every optical fibre is shipped with the same reliability and performance standards that distinguish Corning products from all others.