From the depths of space to the depths of the ocean, our products help enable ground-breaking applications where precision matters. Building on nearly two centuries of materials science innovation, we are leaders in optomechanical design, diamond turning, optical grinding and polishing, ultra-precision machining, and thin film coatings. When you choose Corning, you gain access to our products with remarkable properties. Add our commitment to quality and customer satisfaction, and together we’re reaching new heights.

Corning is a premier supplier of advanced optical solutions and components for the aerospace and defense industry.

Our Solutions

Our Solutions

Interactive Timeline

Realizing Your Vision

Realizing Your Vision

Explore how we've enabled life-changing innovations.

Explore how we've enabled life-changing innovations.

Learn MoreCorning’s Vital Role in the Space Age

Corning’s Vital Role in the Space Age

In 1936, Corning paved the way for a new generation of light-weight telescope mirrors for observatories by casting, at the time, the world’s largest primary telescope mirror blank – The 200-inch Hale Telescope. Since then, our scientists have continued innovating, expanding our capabilities in high-quality transmissive optics and diamond-turned metallic materials. From the world’s earliest quests into the great unknown to current and future missions, we are proud to play a role in making these discoveries possible.

Gallery

Current Project Highlight

Corning's Hyperspectral Imaging Technology Helps Fight Climate Change

Corning's Hyperspectral Imaging Technology Helps Fight Climate Change

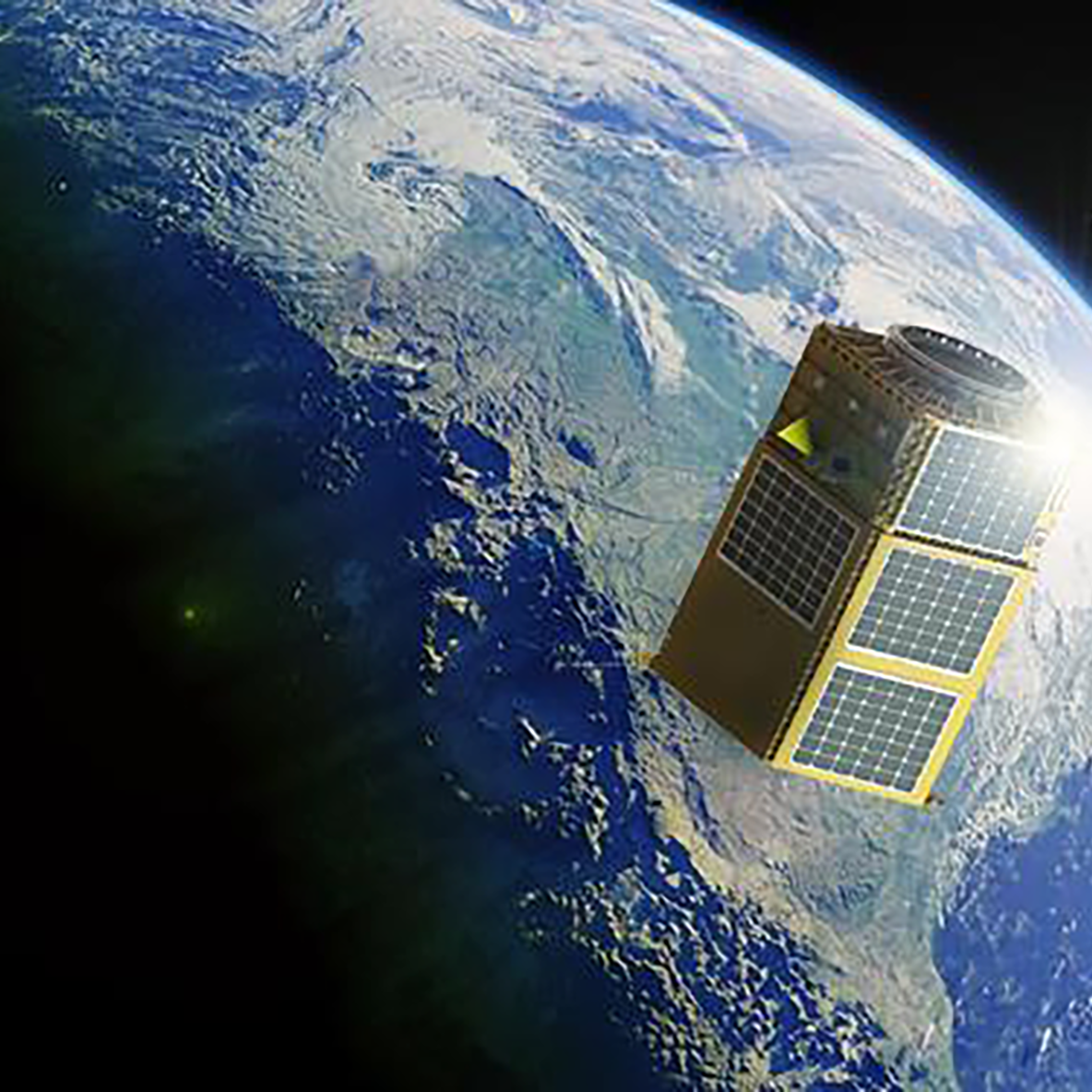

Read MoreNew satellites equipped with Corning’s advanced hyperspectral-imaging technology can detect pipeline leaks and other environmental issues, providing precise monitoring and exploration capabilities for businesses and governments.

New satellites equipped with Corning’s advanced hyperspectral-imaging technology can detect pipeline leaks and other environmental issues, providing precise monitoring and exploration capabilities for businesses and governments.

Corning Aerospace & Defense

Ready to learn more? Contact our team.

Ready to learn more? Contact our team.

We'll help you make your next project a reality with the right products and solutions.

We'll help you make your next project a reality with the right products and solutions.

Contact Us