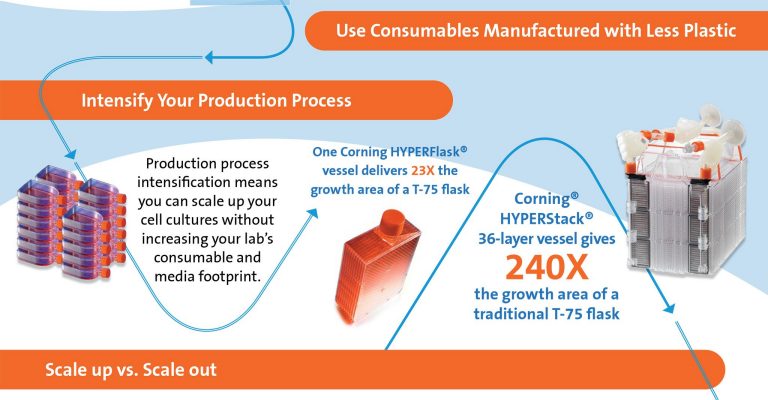

At Corning Life Sciences, we create innovative products and technologies that enable our customers to develop and deliver life-saving therapies. But we recognize our planet’s resources are finite, and climate change presents a real and growing concern, so we are reimagining product development. By incorporating Design for Sustainability (DfS) into our processes, we are bringing a more environmentally friendly and diverse mindset to our innovation efforts, focusing on reducing waste, conserving resources, and promoting circularity.

We carefully select materials to minimize environmental impact, utilizing renewable and recycled options and fostering a diverse supply chain that supports sustainable packaging. Our processes emphasize energy efficiency, renewable energy adoption, water conservation, and waste reduction, ensuring that our operations align with our sustainability goals. We design with the end of a product's life in mind, promoting circularity through education and facilitating reuse or recycling. With these efforts, we are dedicated to creating a healthier future for both people and the planet.