A major challenge in manufacturing adherent cells for advanced therapies is producing the large quantities of cells needed in a cost-effective manner. Corning has developed a novel fixed bed bioreactor (FBR) platform that is designed to deliver significant surface area intensification and high-yield bioproduction capability. The Corning Ascent FBR System is designed to enable process development and production scale cell culture capacities for cell and gene therapy workflows with high yields and viable cell harvest capability that may result in substantial cost savings when compared to existing commercial FBR systems. The Ascent FBR platform currently enables linear scalability from 1 m2 to 100 m2 with efficient process transfer during scale-up with plans for further scaliability in the future.

Overview

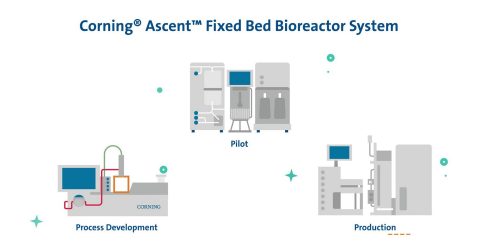

Scaling from Process Development to Production with a High Density Adherent Cell Growth Platform

Scaling from Process Development to Production with a High Density Adherent Cell Growth Platform

About

Learn more about the Ascent Fixed Bed Bioreactor System

The Ascent FBR System:

The Ascent FBR System:

- Features an innovative bioreactor designed to enable uniform media flow to enhance cell health and drive high-density uniform cell growth for a more homogeneous cell population.

- Design attributes enable >90% transfection efficiencies for gene therapy applications resulting in high AAV vector yield/m2, which can lead to fewer required runs, an overall reduction in media and lower operational costs.

- Enables efficient harvest and collection of viable cells, expanding its utility to a broad range of cell therapy applications, allowing the Ascent platform to be used for seed train and production workflows.

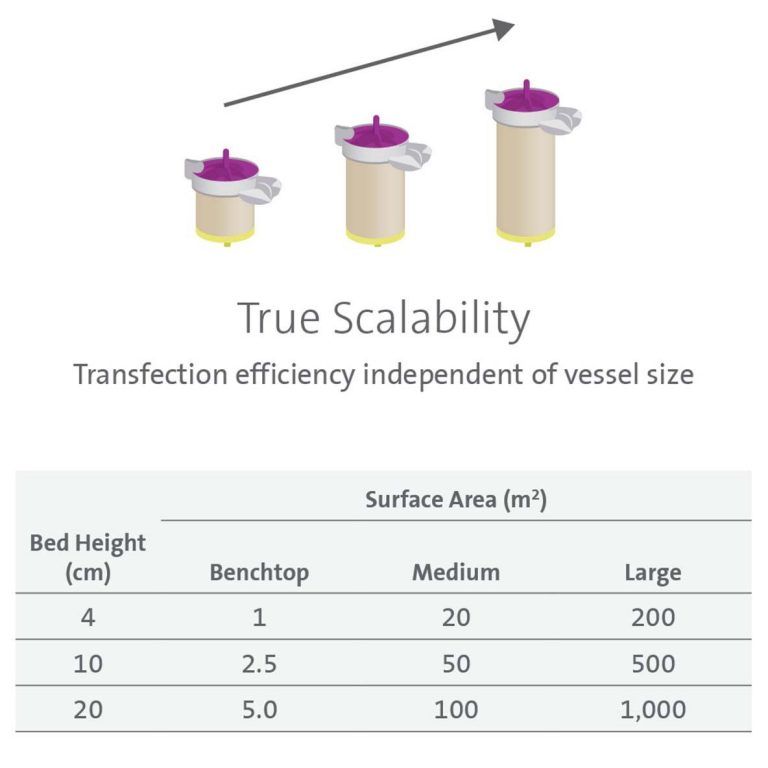

- Offers true scalability across available capacities ranging from 1 m2 to 100 m2.

- Collectively, these benefits maay help drive faster development time to production and significant savings in manufacturing costs.

- Features an innovative bioreactor designed to enable uniform media flow to enhance cell health and drive high-density uniform cell growth for a more homogeneous cell population.

- Design attributes enable >90% transfection efficiencies for gene therapy applications resulting in high AAV vector yield/m2, which can lead to fewer required runs, an overall reduction in media and lower operational costs.

- Enables efficient harvest and collection of viable cells, expanding its utility to a broad range of cell therapy applications, allowing the Ascent platform to be used for seed train and production workflows.

- Offers true scalability across available capacities ranging from 1 m2 to 100 m2.

- Collectively, these benefits may help drive faster development time to production and significant savings in manufacturing costs.

- The Ascent Fixed Bed Bioreactor (FBR) System includes a system controller and single-use components including a bioreactor, media conditioning vessel, and other consumables, such as tubing, connectors, sensors, and bottles.

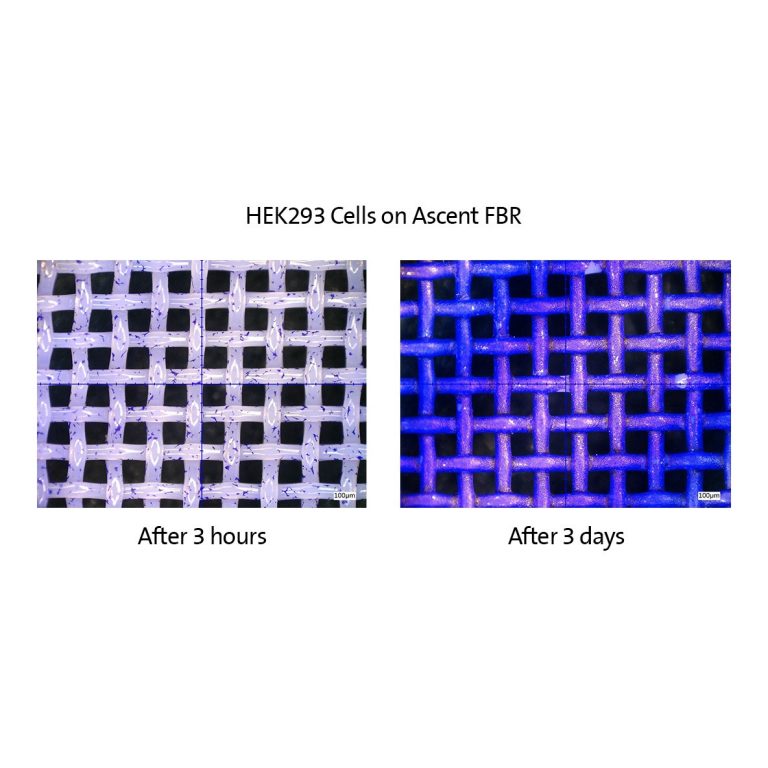

- The bioreactor's specially treated and packed polymer mesh enables uniform, low-shear fluid flow through the bioreactor bed, which promotes evenly distributed cell growth and enhances exposure of cells to nutrients and reagents.

- A separate conditioning vessel and recirculation loop enables flexibility in managing media conditions and developing optimal processes within the platform.

- The controller is designed to provide flexibility in protocol development and hands-off operation during use. Disposable sensors monitor key process parameters (pH, dissolved oxygen, temperature), and all fluid-contacting components are pre-assembled, single-use, and irradiated; no autoclaving required.

- The Ascent Fixed Bed Bioreactor (FBR) System includes a system controller and single-use components including a bioreactor, media conditioning vessel, and other consumables, such as tubing, connectors, sensors, and bottles.

- The bioreactor's specially treated and packed polymer mesh enables uniform, low-shear fluid flow through the bioreactor bed, which promotes evenly distributed cell growth and enhances exposure of cells to nutrients and reagents.

- A separate conditioning vessel and recirculation loop enables flexibility in managing media conditions and developing optimal processes within the platform.

- The controller is designed to provide flexibility in protocol development and hands-off operation during use. Disposable sensors monitor key process parameters (pH, dissolved oxygen, temperature), and all fluid-contacting components are pre-assembled, single-use, and irradiated; no autoclaving required.

Contact Us

Contact Us

If you’d like to see the Corning Ascent Fixed Bed Bioreactor (FBR) System in action, please contact us to request an in-person demonstration.

Request a demo of the Ascent FBR System 5>

If you’d like to see the Corning Ascent Fixed Bed Bioreactor (FBR) System in action, please contact us to request an in-person demonstration.

Features and Benefits of the Fixed Bed Bioreactor

Uniformity drives higher yield

: Uniformity drives higher yieldThe woven mesh of the bioreactor in the Corning Ascent FBR System is designed to enable uniform media flow, cell adhesion and cell growth resulting in significantly higher yield than competitive FBR systems. These images show even seeding of HEK293 cells after three hours (left) and subsequent even cell growth after 3 days (right).

Linear Scalability

: Linear ScalabilityThe Corning Ascent FBR System is designed to provide linear scalability from process development scale to production scale (1 square meter to 1,000 square meters) to create a stable, cost-efficient and well-defined manufacturing process.

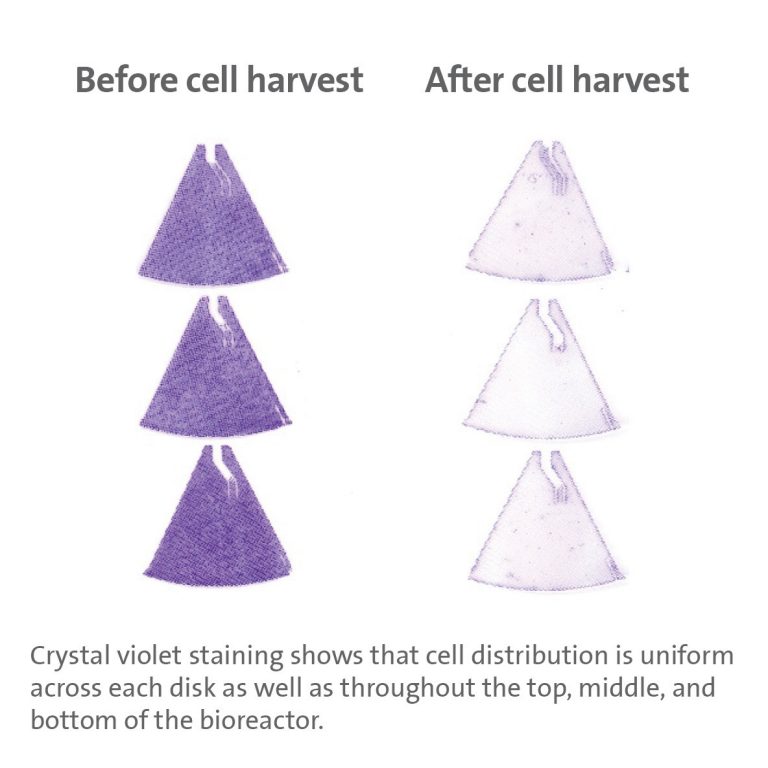

Cell Harvest

: Cell HarvestThe Ascent FBR is designed to harvest viable cells with >90% recovery and to be used for other applications that require the ability to harvest large quantities of cells, such as regenerative medicine and cell-based meat.

Featured Publications

Featured Publications

Expansion of induced pluripotent stem cells under consideration of bioengineering aspects: part 2

This article describes, for the first time, the characterization of the SU Xpansion® multiplate and Ascent fixed-bed bioreactors using both numerical and experimental methodologies, thereby allowing suitable operating ranges to be identified for the bioengineering parameters within which hiPSC growth and quality would be maintained.

Teale, M.A., Schneider, S.L., Seidel, S. et al. Expansion of induced pluripotent stem cells under consideration of bioengineering aspects: part 2. Appl Microbiol Biotechnol 109, 38 (2025). https://doi.org/10.1007/s00253-024-13373-2

Innovative fixed bed bioreactor platform: Enabling linearly scalable adherent cell biomanufacturing with real-time biomass prediction from nutrient consumption

This study demonstrates the effectiveness of the developed fixed-bed bioreactor platform in enabling scalable adherent cell-based biomanufacturing with high productivity and process control.

Goral, V. N., Hong, Y., Scibek, J. J., Sun, Y., Romeo, L. E., Rao, A., Manning, D., Zhou, Y., Schultes, J. A., Tjong, V., Pikula, D., Krebs, K. A., Ferrie, A. M., Kramel, S., Weber, J. L., Upton, T. M., Fang, Y., & Melkoumian, Z. (2024). Innovative fixed bed bioreactor platform: Enabling linearly scalable adherent cell biomanufacturing with real-time biomass prediction from nutrient consumption. Biotechnology Journal. https://doi.org/10.1002/biot.202300635

Featured Resources

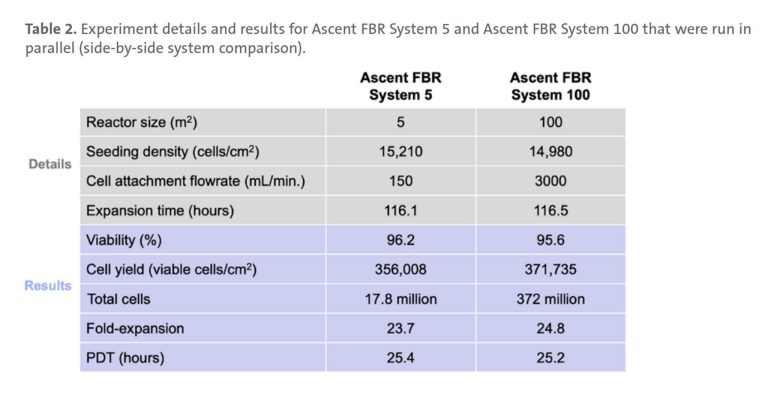

Demonstration of Scalability for the Corning Ascent FBR Platform

Download: Demonstration of Scalability for the Corning Ascent FBR PlatformIn this brief, we present data demonstrating scalability of the Ascent technology using a standard viral vector producing cell line (HEK-293T).

Corning Ascent Fixed Bed Reactor System 100

Download: Corning Ascent Fixed Bed Reactor System 100The Corning Ascent FBR System 100 is an automated, perfusion bioproduction platform for attachment-dependent cell-based processes.

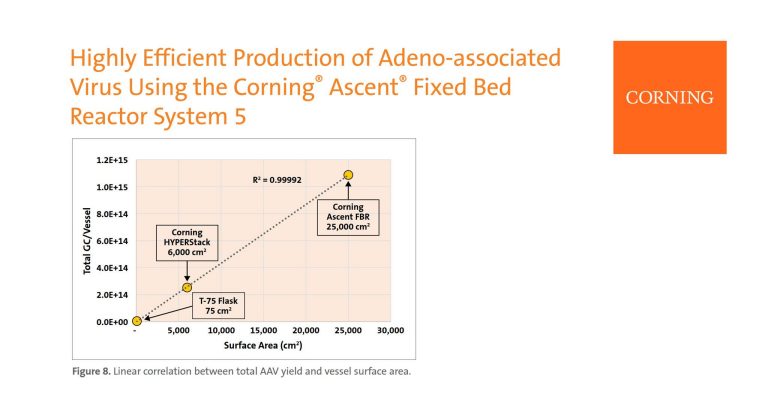

Efficient Production of AAV Using Ascent FBR System 5

Download: Efficient Production of AAV Using Ascent FBR System 5The focus of this study was to demonstrate highly efficient production of AAV in the 2.5 m2 Ascent FBR bioreactor and to compare its performance side-by-side with a comparable FBR system and standard 2D cell culture controls.

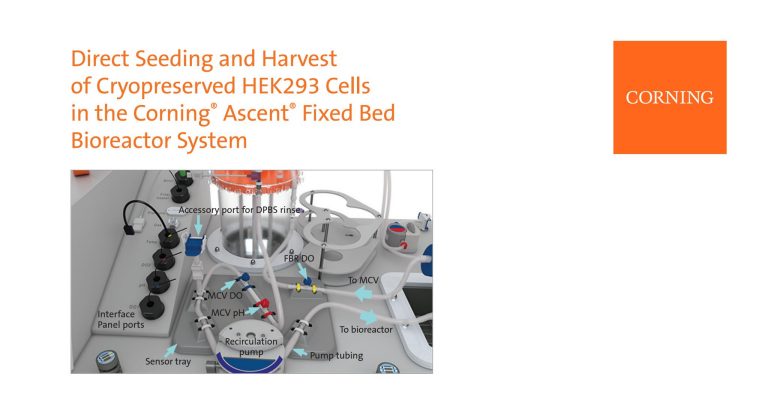

Direct Seeding and Harvest of Cryopreserved HEK 293 Cells in Ascent FBR System 5

Download: Direct Seeding and Harvest of Cryopreserved HEK 293 Cells in Ascent FBR System 5One approach to develop consistency and reduce scale-up time between experiments or production processes is direct inoculation from a single large-volume cell bank, thereby ensuring that the cells are uniform for each batch.

From Bench to Billions: Facilitating Scale-Up of Adherent Cultures for Cell and Gene Therapies

Download: From Bench to Billions: Facilitating Scale-Up of Adherent Cultures for Cell and Gene TherapiesThis guide explores what researchers should consider when creating a risk-mitigating adherent culture process for cell and gene therapy scale-up.

Dyno Therapeutics Scaling Up AAV Production using Ascent Fixed Bed Bioreactor System

Learn More: Dyno Therapeutics Scaling Up AAV Production using Ascent Fixed Bed Bioreactor SystemLearn how Corning scale-up solutions are assisting our customers with their gene therapy development.

Viral Vector Manufacturing and Cell Harvesting from a Single Bioreactor?

Learn More: Viral Vector Manufacturing and Cell Harvesting from a Single Bioreactor?Researchers and commercial producers are now looking at fixed bed reactor (FBR) technology to support growth and scalability in upstream bioprocessing.

Featured Videos

videoplayicon

×

Accelerate Adherent Scale up with the Corning Ascent Fixed Bed Bioreactor System

Watch Now: Accelerate Adherent Scale up with the Corning Ascent Fixed Bed Bioreactor System

videoplayicon

×

videoplayicon

×

Video: Optimizing Cell & Gene Therapy Development with the Corning Ascent FBR System

Watch Now: Video: Optimizing Cell & Gene Therapy Development with the Corning Ascent FBR System

Accelerating Adherent Cell Production for Diabetes Gene Therapy Using a Scalable Fixed-Bed Bioreactor Platform

Watch Now: Accelerating Adherent Cell Production for Diabetes Gene Therapy Using a Scalable Fixed-Bed Bioreactor Platform

Chris Reardon, Associate Scientist, Dyno Therapeutics on Efficient AAV Production Scale-up to Accelerate Gene Therapy Development

Watch Now: Chris Reardon, Associate Scientist, Dyno Therapeutics on Efficient AAV Production Scale-up to Accelerate Gene Therapy Development

Watch the Webinar: Corning® Ascent® FBR - Innovative technology for scalable adherent cell culture

Watch Now: Watch the Webinar: Corning® Ascent® FBR - Innovative technology for scalable adherent cell cultureApplications of the Corning Ascent FBR System Technology

Vaccine Manufacturing and Development

Vaccine Manufacturing and Development

Corning provides a diverse set of single-use products for all your upstream vaccine manufacturing needs.

Corning provides a diverse set of single-use products for all your upstream vaccine manufacturing needs.

Learn MoreAdeno-Associated Viruses Gene Therapy Solutions

Adeno-Associated Viruses Gene Therapy Solutions

Corning offers a portfolio of innovative gene therapy solutions in order to support adeno-associated viruses (AAV) adherent scale-up.

Corning offers a portfolio of innovative gene therapy solutions in order to support adeno-associated viruses (AAV) adherent scale-up.

Learn MoreLentivirus Gene Therapy Solutions

Lentivirus Gene Therapy Solutions

Corning offers gene therapy solutions for scaling up LV adherent cultures from 2D, single-use vessels to large-scale, and production-ready quantities.

Corning offers gene therapy solutions for scaling up LV adherent cultures from 2D, single-use vessels to large-scale, and production-ready quantities.

Learn MoreCell Production

Cell Production

Corning’s cell culture solutions support your cell production goals, orchestrate discoveries in your lab and scale-up cell expansion to mass production.

Corning’s cell culture solutions support your cell production goals, orchestrate discoveries in your lab and scale-up cell expansion to mass production.

Learn More