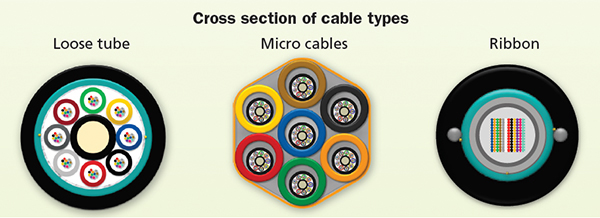

Loose tube, ribbon, and micro loose tube cables are all options for outside-plant fiber cabling

by Derek Whitehurst

Since the development of fiber optic cable in the mid-1970s, there has been a steady stream of innovations in manufacturing, materials, and network systems which have advanced the design and capabilities of outside cables including loose tube, ribbon, and micro loose tube cables.

The cable that started the fiber optic revolution in the 1970s was the loose tube configuration, which isolated the optical fiber from the strains of installation by enclosing everything within fairly rigid protective sleeves or tubes. This design is still widely used today in harsh outdoor environments around the globe.

The 1990s saw the emergence of ribbon cable designs. This cable allowed for higher fiber counts and offered a time and cost savings realized from using mass fusion splicing to speed up network restoration and increase project turnover.

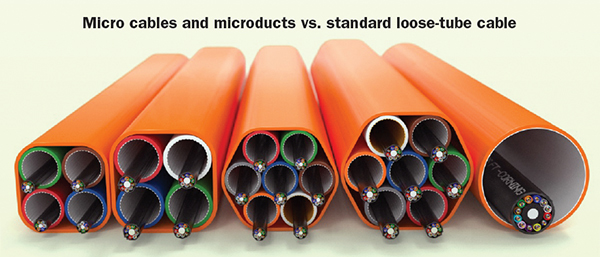

In the early 2000s, micro loose tube cables were first developed in Europe as an innovative approach to installing an optical network in a congested duct environment. These miniaturized stranded loose tube cables, with increased fiber counts per cross-sectional areas, could be installed with less cost and disruption than a rip-and-replace solution.

Typically, customer segments have standardized on one major cable type for their network or environment. However, as networks grow more complex and bandwidth demands increase, it’s becoming more common for multiple cable families to be used in the same network. In this article, we will look at loose tube, ribbon, and micro loose tube cables and how the properties of low attenuation, scalability, and deployment velocity help define where each cable family fits within different segments of the network.

To being with, you should first understand your specific application and the desired capabilities in order to make smart choices concerning fiber optic cabling combinations. And depending on your specific role, certain cable performance attributes will be more attractive than others. For example, a network owner may be focused on deployment velocity or restoration speed, whereas a network designer may focus on system performance. An installer, on the other hand, may be concerned with safety and cable, and hardware ease-of-use.