As Corning Environmental Technologies celebrates 20 years of cleaning the air with light duty diesel particulate filters (DPFs), the business is reflecting on how a critical product innovation progressed. In the first article of this three-part series, we look at the need for emissions control for diesel-powered engines.

For more than 30 years, Corning relied on cordierite – a ceramic renowned for its thermal stability and durability – as the backbone of its emissions-control products. But as diesel engines rose in popularity for light-duty vehicles during the early 2000s, the automotive market demanded solutions that could keep pace with increasingly rigorous emissions standards. This sparked a journey of innovation, culminating in the launch of Corning® DuraTrap® AT diesel particulate filters (DPFs), a new product line that would grow into more than 30 million filters sold in just two decades. But the road to success was marked by ups and downs.

The rise of diesel engines

In the early 2000s, while diesel engines were gaining popularity globally, Europe – particularly Germany – led the charge with nearly half of all cars produced being diesel-powered by 2005. The appeal was clear: diesel engines offered better fuel economy, benefited from lower fuel prices, and featured excellent driving characteristics.

However, this surge in diesel adoption for light-duty vehicles came with environmental and health concerns. Diesel engines emitted particulate matter that contributed to air pollution and posed serious health risks. In response, the European Commission announced significantly tighter particulate matter emissions standards for passenger cars in 2004 that would become mandatory in 2005.

Automakers were under pressure to comply and turned to Corning for a solution.

At the beginning: A challenge

In June 1999, a customer approached Corning with an urgent challenge. Diesel engines were gaining traction, but, due to the limited experience with diesel particulate filters at that time, existing cordierite DPFs were prone to melting under severe conditions. This was a critical issue given the extreme temperatures diesel filters could reach during regeneration, threatening the viability of cleaner diesel cars amidst rising regulatory pressures. Corning was tasked with delivering a filter that could withstand extreme thermal shocks, boast a melting point at least 300°C higher than cordierite, and meet performance metrics for filtration efficiency and pressure drop – all within just three months.

The late Greg Merkel, Research Fellow, and Willard Cutler, DVP & Commercial Technology Director, Corning Environmental Technologies, launched the initial response, leading to the development of Corning PN filters. These zirconium-based filters featured a high melting point (~1,900°C), excellent filtration efficiency, and low pressure drop. While the prototypes’ performance metrics seemed to be ideal, they still failed during vigorous testing. Highlighting the need for a different developmental approach, one that prioritized heat capacity over melting point alone.

Despite this first setback, Corning, driven by its innovative power and deep expertise in material science, rose to the challenge.

> Read the second article of this series: Corning recounts being on the cusp of DPF innovation

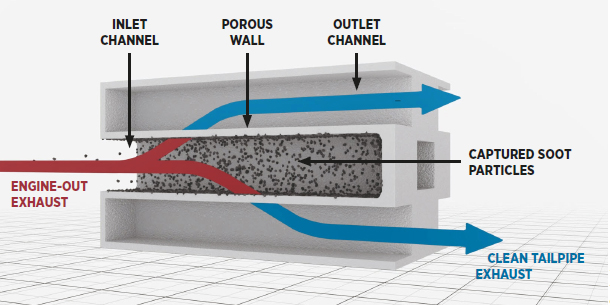

For diesel particulate filters, individual channels are open at one end and plugged at the other, creating a checkerboard face design. Exhaust enters the open (inlet) channels, flows down toward the blocked, or plugged, channel ending at the other side.