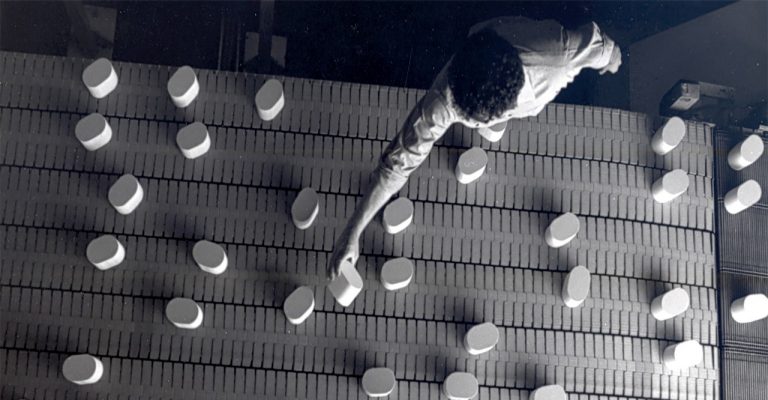

Corning’s scientists work with lasers to determine how light can affect materials.

At Corning, optical physics is part of almost everything we do. It’s in the fiber we use to connect people and places around the globe, and in the displays that make everything from your TV to your phone easier to see. Often, we focus on the ways that we can manipulate materials so that they interact with light in a certain way.

For instance, in fiber, we’re making glass that allows light to travel through it while losing as little as possible. In displays, we’re trying to make images that are crisp and clear.

In some of our applications, though, we study the way that light interacts with materials, instead of the other way around. With lasers, that’s precisely what we do.

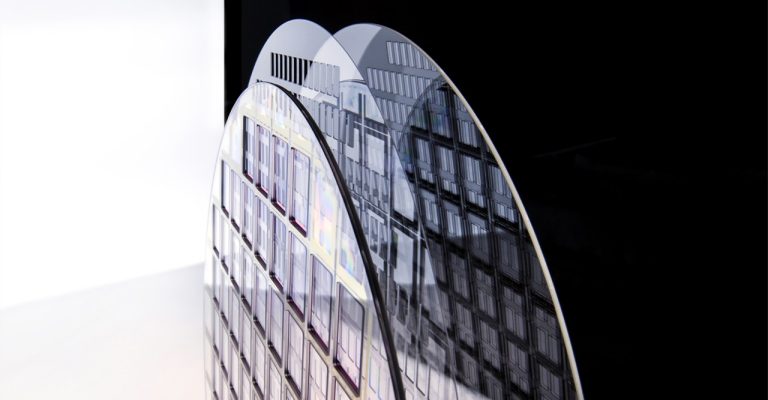

Corning works with lasers to perform a variety of tasks on the glass that we manufacture. Our research teams focus their work on studying glass manipulation and determining which tasks lasers can complete that other technologies may be unable to. Because laser manipulation is an invisible, contactless process where no force is applied, it can also be much more precise. Everything from cutting to drilling to welding can be accomplished using lasers.

Cutting is exactly what it sounds like. It involves taking large pieces of glass and shaping them into smaller sizes. Lasers do this quickly. The beam of light is shot through the entire sheet of glass at once, and the laser creates millions of tiny holes along the edge of the glass. Much like the perforations on a paper towel, these tiny holes make it much easier to break the glass along that pre-defined line. From there, the glass is heated along this line by a second laser, which helps it break.