Corning marks sustainability milestone as Lawrence Livermore National Laboratory achieves fusion ignition

CORNING, NY | Corning Incorporated | December 21, 2022

Corning Incorporated today announced that its advanced optics technologies played a vital role in the latest advancement in clean energy technology. On December 13, Lawrence Livermore National Laboratory (LLNL), in coordination with the U.S. Department of Energy and the department’s National Nuclear Security Administration, reported the first successful fusion-ignition experiment in history.

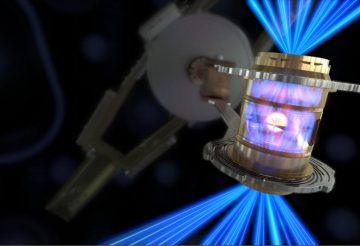

Fusion energy, at scale, could create a cleaner source of energy than current nuclear power, eliminating the pollution, including greenhouse gases and radioactive waste, that nuclear power plants produce.

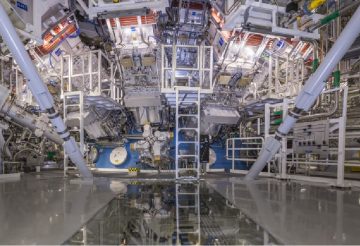

On December 5, a team at LLNL’s National Ignition Facility was able to produce more energy from the fusion reaction than the laser energy used to drive it – a major step toward the successful application of fusion ignition technology. Corning supplied LLNL with directed-energy windows made from Corning® HPFS® Fused Silica. These windows were integral to LLNL’s fusion ignition breakthrough.

“Corning’s advanced optics technologies play an essential role in moving our world forward,” said John Bayne, senior vice president and general manager, Corning Mobile Consumer Electronics. “From our optical components that enabled the awe-inspiring James Webb Space Telescope photos, to our leading solutions in cutting-edge semiconductor manufacturing, to our proprietary glass making augmented and mixed reality devices possible, Corning’s innovations are vital to progress. We’re thrilled to have contributed optical components for LLNL’s fusion experiments, which could ultimately lead to cleaner energy sources that prolong the health of our environment.”

Corning first started working with LLNL in the 1980s during the development of the Nova Laser. At the time, it was the world’s largest high-energy laser, allowing researchers to study nuclear-weapon physics and inertial-confinement fusion. Corning and LLNL extended their relationship in the early 2000s, when Corning supplied HPFS® Fused Silica to the National Ignition Facility, the largest high-energy laser facility ever built. Corning’s HPFS® Fused Silica is the material of choice for high-energy windows and lenses because of its optical properties, thermal stability, and large-size application capabilities.

To learn more about Corning’s history in the aerospace industry, visit: https://www.corning.com/aerospace-defense/index.html