Advantaged properties of ultra low expansion glass include large size capabilities,

extreme thermal stability, no thermal hysteresis, and delayed elasticity.

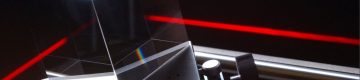

ULE® 7972 is a titania-silicate glass with near zero expansion characteristics that have made it the material of choice in unique applications such as machine tool reference blocks, gratings, reference blocks, interferometer reference mirrors, to telescope mirrors.

- ULE® glass is a single-phase, supercooled liquid with a CTE very near 0 ppb/K.

- EUV ULE® 7973 glass has been tailored to meet the needs for mask and optical substrates for EUVL applications.

- The lithography transition from 193nm to 13.4nm required a major design shift in stepper optics from refractive to reflective. In reflective optics, substrate materials should be purely passive. The incident light should reflect off of the multilayer coatings of the optics and the photomask without the introduction of any mechanical or optical distortion caused by the underlying substrate.

- To minimize distortion from the minute temperature changes and meet the stringent EUVL specifications, the substrates must have a near-zero coefficient of thermal expansion (CTE) and low peak-to-valley (P-V) CTE variations. The extremely low CTE requirements are specified in parts per billion per degree kelvin (ppb/K).

- The demanding CTE requirements are forcing improvements in metrology as well and Corning continues to improve metrology methods to meet EUVL demands.

- Discrete tailoring of the zero cross-over temperature is possible.

TSGTM 7972 Low Expansion Glass is the third member of Corning's titania silicate low expansion glass family. TSG has a relaxed absolute coefficient of thermal expansion (CTE) requirement for those applications that do not require a near zero-expansion material.