The right foundation

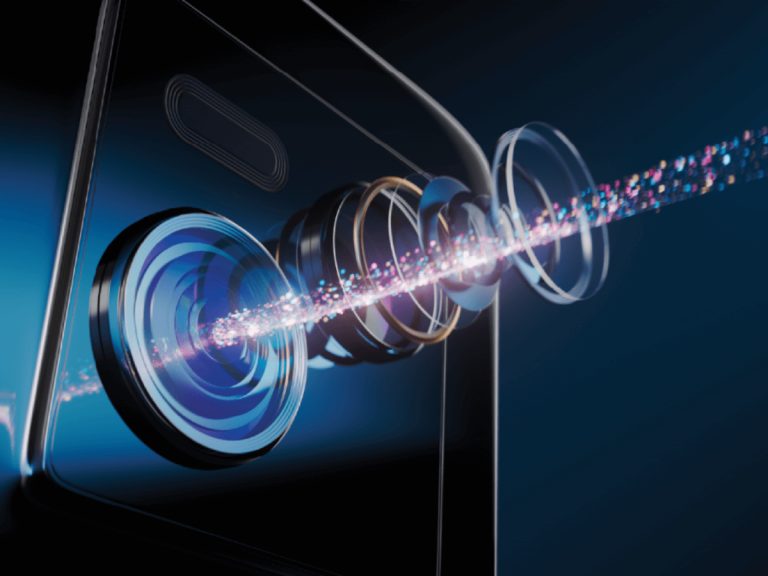

An uptick in Gen 8.x OLED investment demonstrates that device and display panel producers are ready to meet – and exceed – consumer expectations.

But why Gen 8.x, specifically? It’s all about efficiency. This Gen size affords display panel makers the flexibility to efficiently produce medium-sized devices, like notebooks.

Producing a glass that is both large enough to be efficient for mid-size displays and high-performance enough for OLED's more stringent panel requirements, will require a balanced glass composition.

The light display glass is a critical component for panel makers who need to use higher processing temperatures and thicker copper lines to produce a high-performance panel with a narrow bezel. Their panels will benefit from a glass substrate with enhanced thermal and dimensional stability.