Fifty years ago, a pair of physicists in a Swiss laboratory began untangling a mystery that had been intriguing a handful of other scientists for several years.

Here was their conundrum: Could miniscule electrical jolts unwind the spiral molecular structure of a new substance known as “liquid crystal,” causing the crystals to block light, then re-twist them and allow light to pass through again?

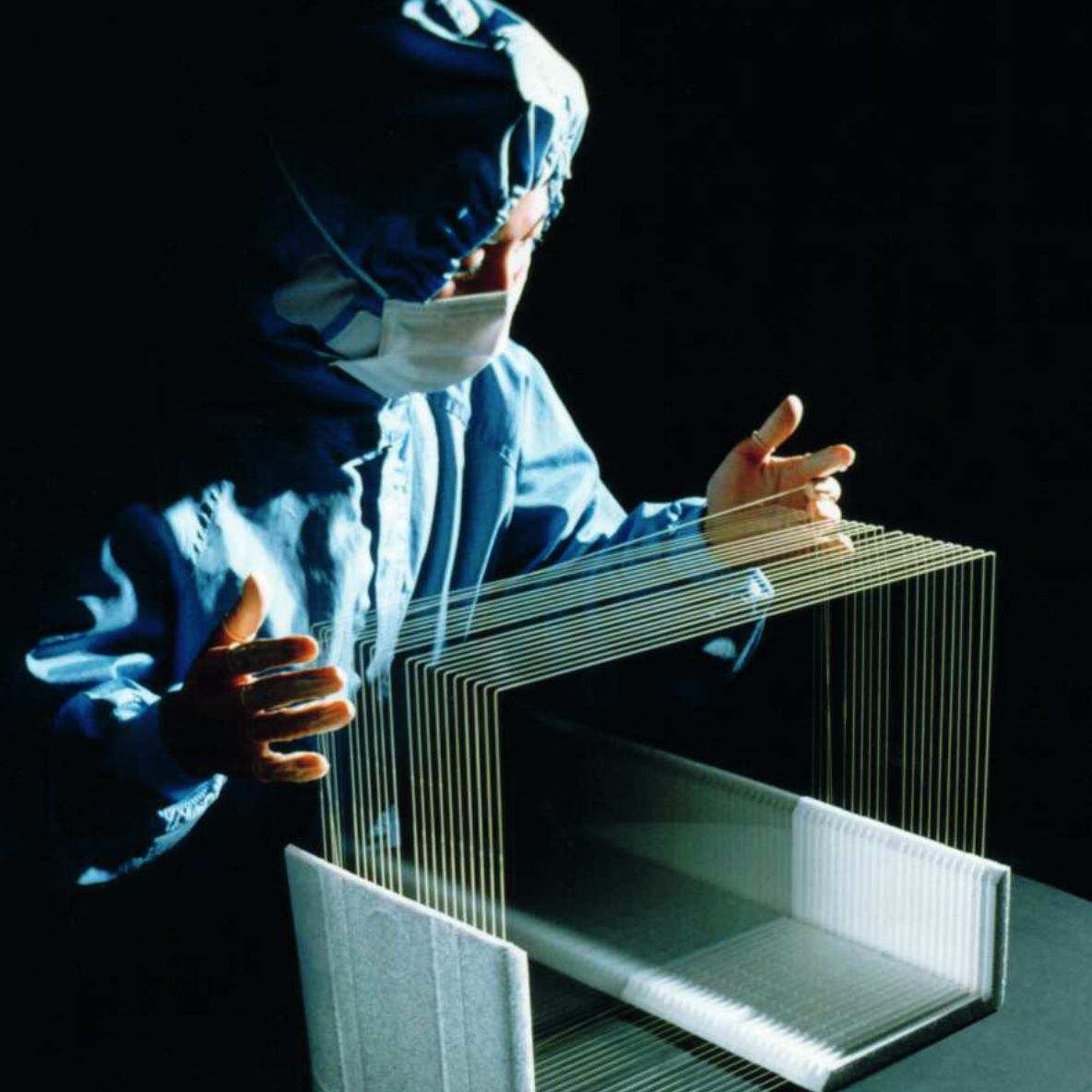

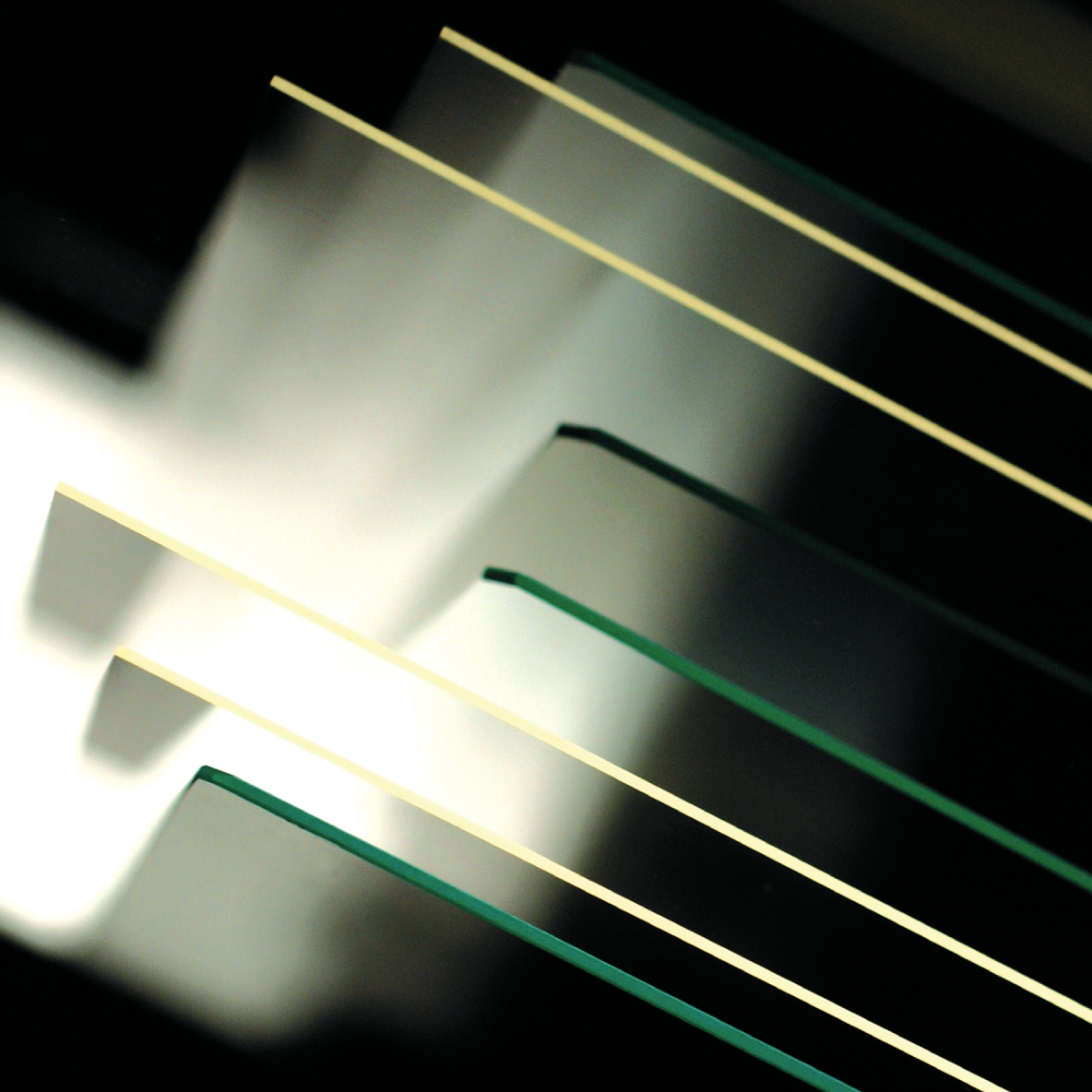

The physicists – Dr. Martin Schadt and Dr. Wolfgang Helfrich – placed the liquid crystal between two plastic surfaces carrying a grid of transparent electrodes. In so doing, they discovered they could create individual picture elements, or “pixels,” which could be used to form shapes.

They filed a Swiss patent for the idea on Dec. 4, 1970. Though it attracted scant attention at the time, the milestone now stands as the birthdate of the liquid crystal display (LCD) – the technological platform which has transformed consumer electronics and presented a brilliant new way to view the world.

Early LCD developers took a few years to figure out that specialty glass, not plastic, was the best stable substrate for the delicate LCD circuitry and the color backplane component. Once they did, they turned increasingly to Corning to supply them with extraordinarily stable, flat, fusion-formed glass, able to preserve the critical properties of the liquid crystal and withstand high processing temperatures.

And LCDs rapidly transformed from “passive matrix” models, mostly used in pocket calculators and digital watches, to “active matrix” LCDs in which each sub-pixel was controlled with an isolated thin-film transistor. AMLCDs enabled wide viewing angles; brilliant, fast-moving images; and high-resolution images that had never been possible before.

Corning Incorporated was a critical player in this development, and eventually became the world’s leading supplier of LCD glass substrates. And Corning® EAGLE XG® Glass, the world’s first LCD substrate with no arsenic or other heavy metals, went on to exceed sales of 25 billion square feet, making it one of the most successful products in Corning’s history.