Forming and Finishing

Forming capabilities include computer numerical control (CNC) machining and shaping of optics, specialized grinding equipment, diamond turning, and precision metal machining. Finishing capabilities include conventional polishing, proprietary super and deluxe polishing, magnetorheological finishing, and ion beam etching.

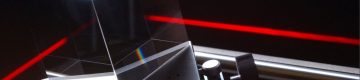

Coating

Corning specializes in high-end, ultra-precise coatings and offers a variety of over 200 proprietary coating designs covering the full spectrum from deep ultraviolet (DUV) to infrared (IR), wavelength-specific blocking coatings, protective coatings, and high-end transmissive coatings.

Optical Assembly

Corning delivers complete opto-mechanical sub-assemblies including design, materials, components, and optical sub-assemblies.

Additional Resources:

Bow, Warp, TTV: Definitions and Method of Measurement

Watch Corning's Fusion Process video