This article was first published in the March 2022 edition of Update, a SAE member magazine.

Each year, over 10 million people — that’s roughly the population of New York City — die prematurely because of exposure to fine particles emitted as a result of fossil fuel combustion. Also known as PM2.5 to denote sizes less than 2.5 microns, these are particles about 30 times smaller than the diameter of human hair. The small size helps these particles make their way deep into the lung, causing a range of cardiovascular health effects and allowing them to be transported to other organs. Recently, nanoparticles were even found in brain cells, where they increase the risk of stroke, dementia, and a variety of other negative health effects. Unfortunately, these health effects are borne disproportionately by poor communities, people of color, and minorities living in areas near highways with elevated pollution levels.

Considering the adverse health effects, the World Health Organization (WHO) recently recommended a 50% reduction in PM2.5 (from 10 to 5 mcg/m3) levels for healthy air. The U.S. Environmental Protection Agency (EPA) is also considering revising the annual PM2.5 national ambient air quality standard (NAAQS) down from the current level of 12 mcg/m3 to 8–10 mcg/m3.

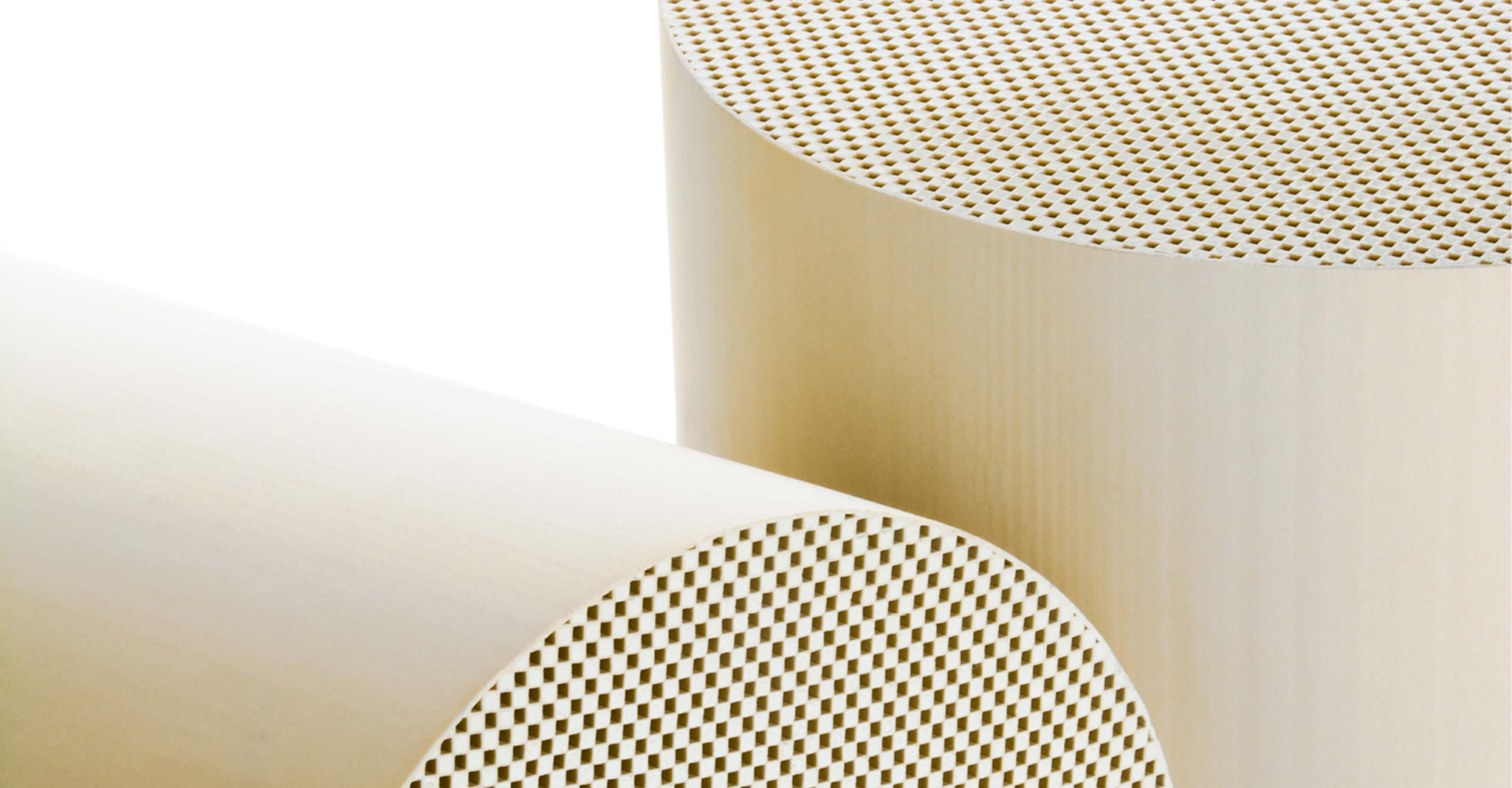

What tools do we have to eliminate tailpipe particulates? All modern diesel engine powered cars and trucks have been equipped with diesel particulate filters (DPFs) for two decades now, resulting in significant reductions of soot emissions. However, particulate emissions from modern gasoline vehicles have actually increased, due to the adoption of direct injection technology. As a result, Europe and China have introduced particle number regulations that enforce the use of “gasoline particulate filters,” or GPFs, on modern light-duty cars and trucks, resulting in deep reductions of tailpipe emissions. GPFs are very similar to diesel filters in their fundamental operating principle, but with material and porosity design changes implemented to account for the application differences.

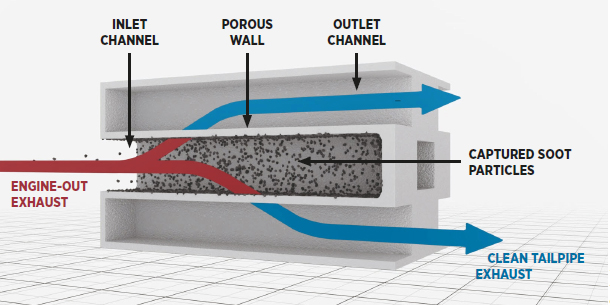

As to be seen in the sidebar image, the filter is a honeycomb structure with channels plugged in a checkerboard pattern at alternate ends. These plugged channels force the gas to flow across the porous walls, which collect soot and ash. These “wall-flow” filters are mostly made of cordierite, as this material offers excellent thermal shock resistance and quick heat-up. They are added either in the “close-coupled” or “underfloor” position, which refers to the distance from the engine, and can either be deployed in the bare state or catalyzed with a three-way catalyst coating to enable gas conversion in addition to high filtration.

Accordingly, Corning has introduced two families of products: DuraTrap GC with ~55% porosity and 200/8 cell design for uncatalyzed applications and DuraTrap GC HP family with a high porosity of ~65% and a 300/8 cell design for catalyzed applications. A “300/8” design refers to cell density of 300 cells per square inch and wall thickness of 8 mils.

Commercially available filters already offer high filtration efficiency. Even higher filtration products are being developed to meet upcoming Euro 7 standards, which will cover extreme real-world driving conditions and include particles down to 10 nm. The new filters will have novel hierarchical pore structures, which promise very high filtration efficiencies in the fresh and clean state, without any soot or ash.

An increase in filtration is typically associated with an increase in pressure drop, but using this technology, the additional filtration comes with little pressure drop penalty. In fact, with some soot accumulation, the new GPFs offer lower pressure drop. Unlike engines and catalysts, the performance of filters only improves with mileage.

There are other benefits to adding a GPF to an emissions control system. Analyses of soot particles have shown the presence of adsorbed carcinogenic polyaromatic hydrocarbons (PAHs), products of incomplete combustion. Catalyzed GPFs have been shown to remove >99% of these PAHs. Also, soot particles are composed in large parts (>75%) of black carbon, which is a greenhouse gas agent with 3,200 times higher global warming potential than CO2. The filters therefore help reduce the climate change impact of tailpipe emissions.

Policymakers across the world are looking to transition fleets to zero tailpipe emitting electric vehicles, so it’s fair to ask whether we should invest in additional technologies for internal combustion engines (ICEs). It should be noted that in the U.S. alone, ~15 million vehicles are sold each year, with battery electric vehicles representing only 3% of that market. Assuming all vehicles sold are electric by 2035, calculations show that GPFs can help avoid almost 30,000 tons of particulate emissions in the next two decades. This suggests the need to adopt a pragmatic approach, adding the best available, costeffective, and proven technologies to make ICE fleets as clean as possible.

The U.S., traditionally the world leader in setting tailpipe standards, is unfortunately lagging on this topic. Current mass-based standards do not enforce GPFs. This has resulted in similar vehicle models being sold in Europe and China with filters and in the U.S. without filters. Upcoming regulations will hopefully resolve this situation. Modern ICE vehicles can reach near-zero levels of emissions if equipped with advanced emissions control technologies. In fact, on-road measurements show that the tailpipe particulate emissions for vehicles with filters can be lower than the ambient concentrations of highly polluted cities. In some places, the exhaust coming out of your car is cleaner than the air around it — and to me, that sounds like progress!

"[...] the filter is a honeycomb structure with channels plugged in a checkerboard pattern at alternate ends."

"[...] plugged channels force the gas to flow across the porous walls, which collect soot and ash."