“It’s exciting to see the dedication and commitment of the students and coaches result in national recognition,” said Sam Zoubi, director, Modeling, Software & Analytics. “A wealth of talent exists in our Corning Valley communities – something that continues to benefit our company and the larger area.”

Sam has been engaged with the program since 2004, when he got involved as a parent with Mike Al-Zoubi, who now is a manufacturing engineer with Corning Pharmaceutical Technologies. Since then, Sam has worked with hundreds of students – some of which have gone on to solve real-world technology problems at Corning. “I’ve been doing this so long, and every year, the students are going on to achieve greater things,” Sam said. “The program continues to give back to our people, to the community, to technology – it’s an interconnected tradition. It has been a massive part of my life for nearly 20 years, and I’ve watched it grow into the experience that it continues to be to this day.”

The Robotics program has also extended their outreach to host program chapters in Keller, TX, and several locations in North Carolina near Corning facilities. The program’s impact reaches on a global scale, too, extending as far as Rwanda in East Africa. Carlos Alonzo, technology project manager, Corning Automotive Glass Solutions (AGS), launched a Robotics program in Rwanda with Eric Biribuze, director, Commercial Operations & Business Excellence (AGS) and founder of the non-profit organization, STELA. Carlos is looking forward to getting the program in Rwanda up and running again in the fall, which, recently, has been an obstacle due to COVID-19. “Despite the challenges of having to remote in and convey thoughts and ideas digitally, you can still see their eagerness to get the program going,” Carlos said.

The robotics club’s success stems from its core cause: to deliver both soft and technical skills to the community that can be used in a professional setting, no matter the field the students intend to pursue. That goal goes beyond robotics and into Corning’s facilities, where students are given the opportunity to apply for industrial experience through an internship at the Sullivan Park campus – a liaison between robotics and Corning, giving 10-12 high school students life-changing exposure and experiences. The internship program is supported by Jason Harris, manager, Modeling, Software, and Analytics, who also participates in the robotics program as a judge and referee. “These students that join the internship program get a taste of Research & Development before they graduate high school,” Jason said. “We give them meaningful projects to work on in real time. It’s something that’s invaluable to Corning to be able to give this opportunity to the future that resides right in our community.”

“We often mistake our interns with college students and employees,” said Sam. “Our interns are well beyond their years, and I continue to be amazed by the things they accomplish.”

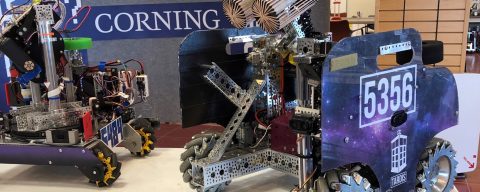

Click here to learn more about Corning Area Robotics.