The Corning HYPERStack cell culture vessel features a unique, ultra-thin gas-permeable film to eliminate the air gap within the vessel. This results in a substantial increase in cell growth surface area compared to traditional vessels of comparable cubic footprint.

With Corning HYPERStack cell culture vessels, you can scale your production from the 6,000 cm2 of a single 12-layer module to multiple manifolded 36-layer modules delivering more than 500,000 cm2 of closed system cell growth area.

From viral vector vaccine production to stem cell therapy, Corning HYPERStack vessels offer benefits, such as:

- Higher total cell yields– provides up to 5X the growth surface area of a traditional cell culture vessel of comparable footprint

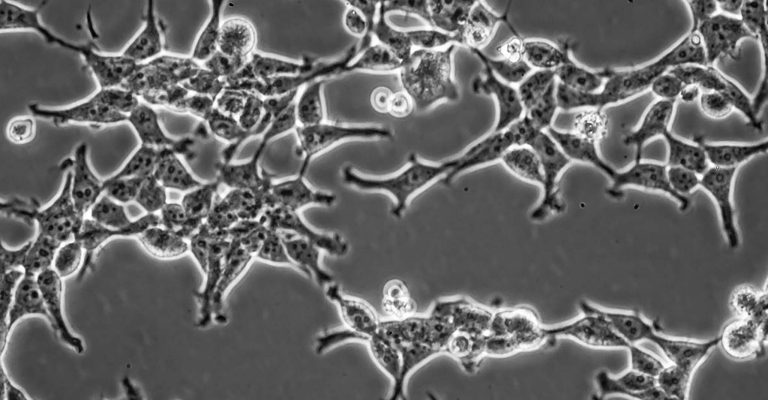

- Similar cell morphology, phenotype, and growth compared to traditional vessels

- Closed system design ideal for large scale cells, protein therapeutics, stem cell therapy, extracellular vesicles, vaccines, and virus production

- Scalable product with multiple size offerings to support scale-up and scale-out

- Innovative assembly and ergonomic design

- Less volumetric waste—offers a fixed media volume of 0.2 mL/cm2 fills

Corning has more than doubled our manufacturing capacity for HYPERStack vessels and upgraded the vessel's design with exterior improvements that enable faster fill and harvest.

The HYPERStack Nest can help to improve process control by consistently placing the vessel in the optimal positions and angles during use.

In addition to offering this innovative cell culture platform, Corning is also pleased to offer valuable field application specialist expertise to assist with your latest scale-up challenge.