As consumer electronics continue to incorporate more engaging user experiences, sensors are playing a vital role in making these devices smarter. Years ago, a typical mobile phone had only one sensor. However, as technology has advanced, the number of sensors per device has increased, and today’s mobile phones often have seven or more sensors in each device. Sensors have enabled us to do incredible things, like unlock our phones through facial recognition and enhance online shopping experiences through augmented reality. This technology, once seen as ideal for the small form factor of mobile phones, is now expanding to new markets. Sensors will soon be everywhere.

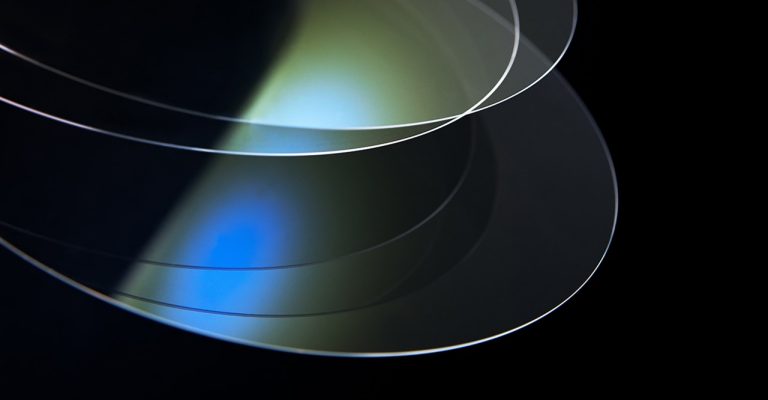

Corning has a suite of optical glasses ideal for sensing applications, including a range of material compositions optimized for CTE, refractive index, and dielectric properties. Our rich history and experience in material science and optical physics has allowed us to develop high-quality glass solutions for next-generation sensors using precision-made, optical glass wafers. These optical glass wafers are used to make micro-optic components for sensing applications, including refractive and diffractive optical elements, lightguides, meta lenses, IR and UV filters, and more.

From Corning® HPFS® Fused Silica to fusion-drawn optical glasses, we have a variety of materials with tightly controlled geometric tolerances to meet demanding customer requirements for wafer-level optic applications. Various melting, forming, and finishing methods enable significant volume supply of these high-precision wafers. Our highly technical glasses paired with supporting capabilities for coatings, structuring, processes, and world-class metrology makes Corning an ideal supplier of glass for sensing technologies.