Interview with Dr. Yi Jiang, president and general manager of Corning Advanced-Flow Reactor Technology Co., Ltd.

The chemical industry is having a major impact on China’s national economy and the lives of its citizens. Inherently safer production could play a role in supporting both. China Chemical Industry News (CCIN) reporter, Mr. Hongying Chen recently interviewed Dr. Yi Jiang, president and general manager of Corning Advanced-Flow Reactor Technology Co., Ltd. on how microchannel reactor technology (with flow chemistry) – a disruptive innovation, could be adapted to enable a more intelligent and safer chemical industry.

Since the "3.21" explosion at the Xiangshui Chemical Plant in Jiangsu Province, more stringent measures for safety and environmental protection have been introduced, requiring the chemical industry to convert from its conventional technology and batch equipment to inherently safer continuous flow technology.

To some extent, China's chemical industry, especially the fine chemical industry, got a late start with relatively old, small scale, conventional technology and batch equipment. Some dangerous reactions in the chemical production process, such as nitration, hydrogenation, chlorination, sulfonation, etc., have fast reaction rates and are highly exothermic in nature. If the heat transfer of the reactor is not timely, this can easily result in " temperature runaway", "material clashing" and even explosions. Dr. Jiang said that in order to address safety concerns with chemical production, manufacturers and the industry must closely monitor process safety versus regulation requirements, while also increasing their investment in new technologies.

According to Dr. Jiang, microreaction technology has been recognized as a disruptive innovation in the chemical industry and has been implemented in several applications at commercial scales. Compared with traditional batch reactors, micro-reaction technology can save space, manpower, time and cost, while also improving productivity, product yield, and purity. Microreactor technology is an inherently safer chemical production method with extremely low chemical holdup, and continuous and controllable processing with high automation. It enables significant economic and social benefits and is a key technology in enabling intelligent manufacturing in the future. At present, there have been many successful cases of industrialization using continuous flow microreactor technology all over the world. Corning has implemented many sets of continuous flow production platforms with total annual throughput exceeding 10,000 metric tons for customers.

However, general adoption of continuous flow chemical processing has been slow for several reasons. There is a lack of training as many undergraduate and graduate programs do not currently include flow chemistry in their curricula and many chemical industry practitioners still focus mainly on traditional batch processing methods, and do not know much about micro-chemical processing or flow chemistry.

"We’re working to promote the benefits and advantages of flow chemistry to chemical manufacturers across the industry, " Dr. Jiang said. “However, making the shift to a new technology requires a change in mindset that can be challenging for some.”

Secondly, microchemical technology and flow chemistry require a variety of talents, including experience in and knowledge of chemical synthesis and chemical engineering, knowledge of the mechanism, reaction kinetics of organic chemistry, and basic knowledge of fluid hydrodynamics, mass transfer, heat transfer, process scaleup, process analytic technique (PAT), automatic control and system process. At present, there is a serious shortage of continuous flow synthetic technicians in China and around the world. Without fundamental research and development on fluid hydrodynamics, reaction kinetics and chemical synthesis mechanism, and without deep knowledge of process and equipment materials and collaboration of talents in system control and integration, it is challenging to achieve continuous and stable synthesis of micro-reactions, while at the same time achieving inherently safer industrial production.

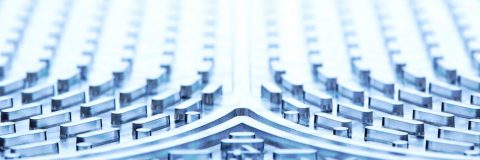

Dr. Jiang emphasized that inherently safer microreactor industrialization is driven by the use of high-quality materials and superior equipment design. Microreactors are often regarded as a process-intensification technology, but have high requirements for the integration of flow modules and microchannel materials, equipment design and system integration. The high heat-transfer area per unit volume of microchannel module ensures 1,000 times better heat-transfer, and requires very high chemical stability of the material surface on the process side of the microchannels. Process intensification greatly improves the reaction speed, while the pressure, mechanical stress and thermal shock stress of the reactor system are also increased. The time-response speed requirements are also greatly increased.

To overcome these obstacles, and more swiftly advance adoption of this technology, Dr. Jiang offered several suggestions, including:

- Introducing flow chemistry and continuous flow reactor technology into undergraduate and graduate programs, textbooks and lab experiments to popularize flow chemistry education and ensure chemists and chemical engineers coming into the pipeline are trained in a purposeful way.

- Standardizing the entry threshold of the microreactor industry, and carrying out industry standards in regard to equipment materials, performance and other aspects, beginning with the requirement of inherently safer production.

- Appealing to government and industry leaders to provide incentives to microreactor suppliers and microreactor application enterprises, such as tax incentives, or other forms of financial support.

- Increased emphasis on the protection of intellectual property rights, and encouraging innovation, enabling the micro-chemical industry to enter a healthy virtuous circle, and ensuring the sustainable development of micro-chemical technology and related enterprises.

--

Based on an article published by China Chemical Industry News (CCIN) in Chinese by Mr. Hongying Chen on July 25, 2019.