Hale Telescope

Corning took a huge step toward its astronomical future by casting what was, at the time, the world’s largest primary telescope mirror. The primary mirror for the 200-inch Hale Telescope in California was cast out of Pyrex borosilicate glass and delivered to Caltech in the spring of 1936. Since manufacturing the Hale Telescope primary mirror blank, Corning has supplied many mirror blanks for astronomy tools worldwide.

Ultrasonic Delay Lines

Corning supplied fused silica for ultrasonic delay lines used by the United States military to detect Soviet missiles. This became the first commercial application for fused silica.

Harlan J. Smith Telescope

Corning supplied the 2.7-meter fused silica primary mirror blank for the Harlan J. Smith Telescope, which is located at the McDonald Observatory near Austin, Texas.

Nova Laser

Corning developed the Schlieren Windows made of fused silica for the Nova Laser at Lawrence Livermore National Laboratory (LLNL) in Livermore, California. The Nova Laser, the world’s largest high-energy laser at the time (10 beams), allowed researchers to study nuclear-weapon physics and inertial confinement fusion. This laser was in operation from 1984-1999.

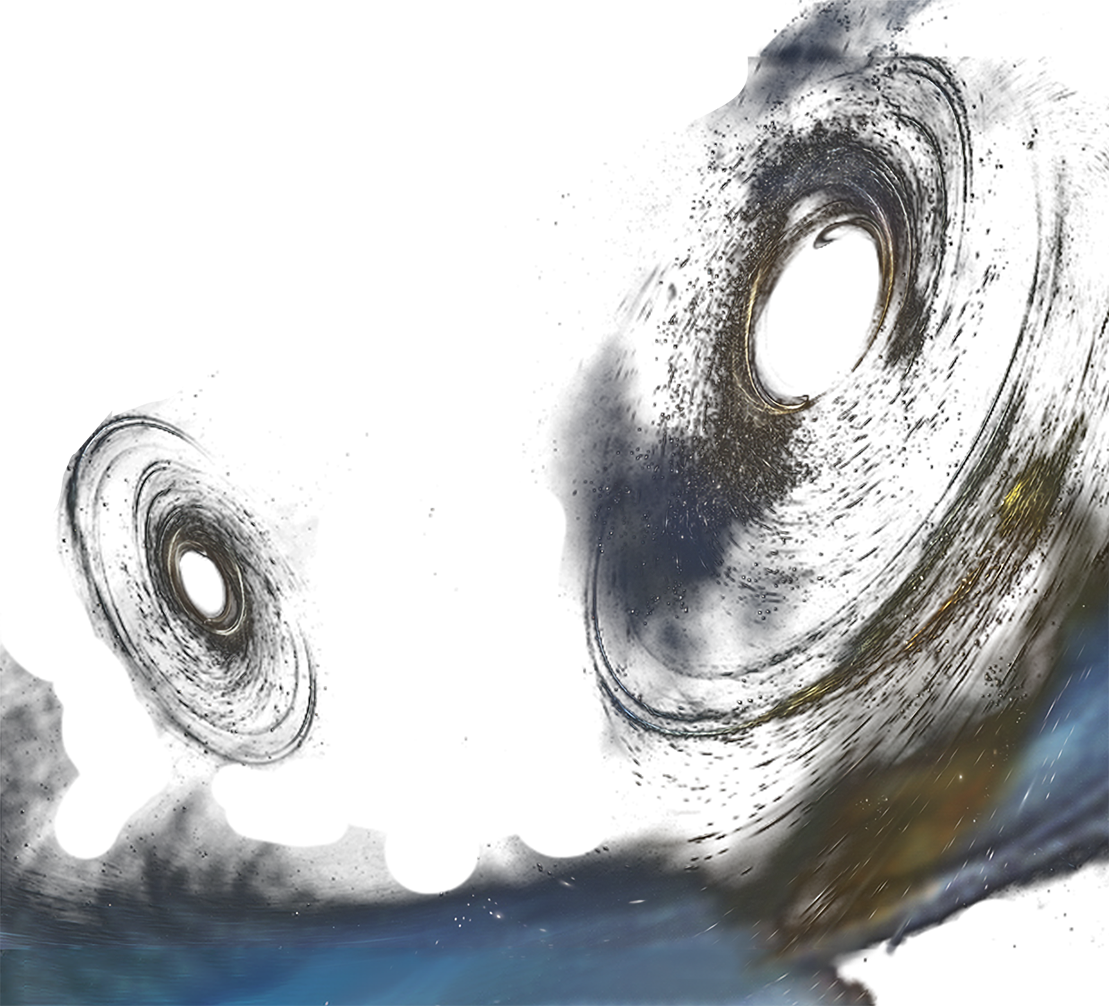

Laser Interferometer Gravitational Wave Observatory

Corning supplied HPFS lenses to the Laser Interferometer Gravitational Wave Observatory (LIGO) in Hanford, Washington and Livingston, Louisiana to allow scientists to better study gravity and learn more about black holes and gravitational waves. Laser beams reflect off the fused silica optics to allow better detection.

Lowell Discovery Telescope

Corning produced and delivered the ULE® primary mirror blank for the Lowell Discovery Telescope (LDT) in Arizona, formally called the Discovery Channel Telescope. The LDT can accommodate five attached instruments at once.

National Ignition Facility

Corning supplied HPFS optical blanks for the Lawrence Livermore National Laboratory’s National Ignition Facility (NIF) in Livermore, California, the largest high-energy laser facility ever built. Its 192 laser beams allow researchers to access the extreme conditions relevant to the cores of stars and giant planets and inside nuclear weapons. These conditions enable NIF to conduct research to support the U.S. Stockpile Stewardship Program and provide invaluable insights into the prospects of clean fusion energy.

Orion Laser

Operated by the UK’s Atomic Weapons Establishment (AWE) in England, the Orion Laser became operational in 2013 to study plasma and nuclear physics. This high energy laser uses optical blanks made from HPFS.

Laser MégaJoule

The Laser Mégajoule (LMJ) is a high-energy laser operated by the Commissariat à l'Énergie Atomique (CEA) and located in Fr ance. This laser will be the largest, most powerful laser in the world with 240 individual laser beams. LMJ will be used to study stars and their environment, gain a better understanding of nature and the origin of the universe, and study high-energy-density physics, plasma physics, and laser-induced nuclear energy. Corning has been supplying HPFS for this project since 2018, and the laser is expected to begin operations in 2022 or 2023.

Vera C. Rubin Observatory

Corning delivered the secondary mirror made from Corning® ULE® Glass intended for the Vera C. Rubin Observatory in Chile in 2009. Once complete, the telescope will explore dark energy and dark matter and map the formation and structure of the Milky Way as well as small objects in the solar system, particularly near-Earth asteroids and Kuiper belt objects. The observatory will also detect transient optical events such as novae and supernovae. Its approximate start of operations is in October 2023.