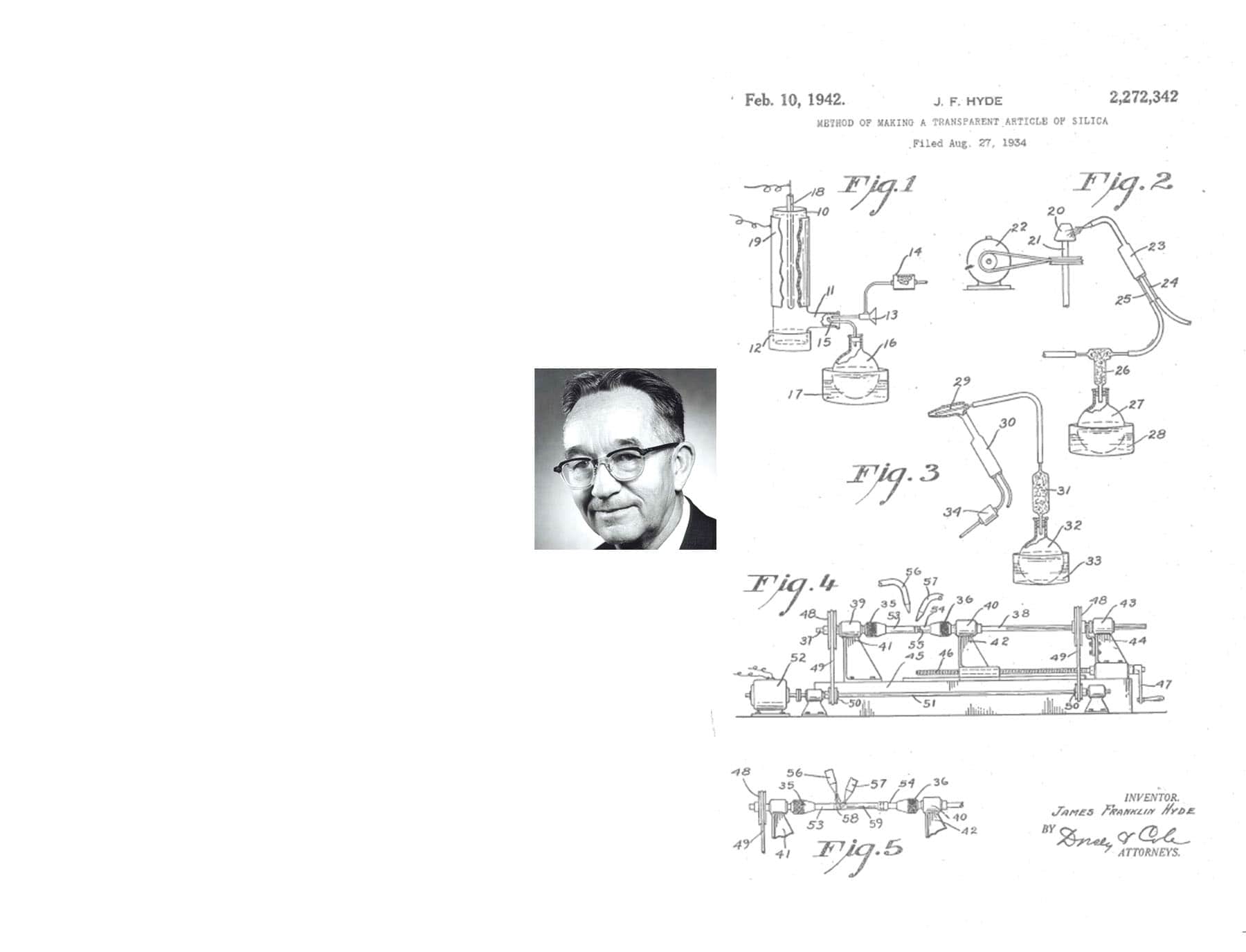

1934

Invention of Fused Silica

While working on the PYREX® 200-inch disk, Dr. James Franklin Hyde developed a chemical process to make the most immaculate commercial glass product on Earth: fused silica.

After you see something work, then you realize that it’s not so complicated after all.

Listen to fused silica expert Larry Sutton talk about how chemical vapor deposition differs from traditional glass manufacturing: